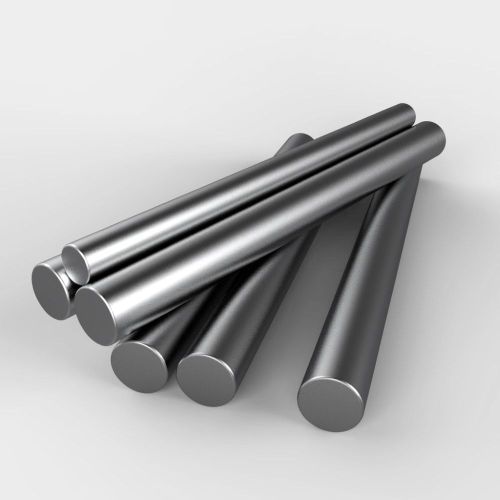

Inconel® 600 Alloy rod 10-200mm 2.4816 round bar (length : 0.3 Meter, diameter : 40mm)

- Do you need a different steel quality or dimension? Please write to us. Our sales team makes an offer from stock program or delivery program :)

- Cuts from 100mm to 1000mm, thicknesses from 10mm and up to 200mm

- Areas of application: furnace construction; reactor construction; suds container; Plant components for the production of chlorine, hydrogen chloride and fluorine; automotive industry (HT sensors, bursting discs for airbags); Manufacture of vinyl chloride (reaction vessels, heat exchangers);

- Didn't find the sizes you wanted? Just contact us! We are happy to help you with your request

Customer ratings and reviews

Durchschnittliche Bewertung

5

review(s): 4

- 4

- 0

- 0

- 0

- 0

Length tolerance is +/-2mm.

- Production time: 5-7 weeks

- Preparation for shipment: 2-3 business days

- Delivery time: depends on the shipping service; please refer to our FAQ for details

Inconel® 600 (2.4816) is a high-temperature nickel-chromium-iron alloy known for its excellent resistance to nitriding, carburizing, and oxidizing environments. This material withstands acids such as acetic, formic, hydrofluoric, and fatty acids, as well as ammonia, chlorine, and hydrogen chloride (up to about 500°C). It is also highly resistant to stress corrosion cracking and maintains good mechanical properties across a broad temperature range, up to a maximum of 1050°C. The high nickel content makes it stable in reducing environments, and it cannot be hardened by heat treatment.

Inconel® 600 is widely used in furnace construction, including the production of transport rollers and seals. It is also suitable for reactor construction (such as reactor vessels and steam dryers) and is ideal for tubs and pipes due to its resistance to alkaline solutions. Additional applications include components for chlorine, hydrogen chloride, and fluorine production, the automotive industry (e.g., HT sensors, airbag bursting discs), manufacturing of vinyl chloride (reaction vessels, heat exchangers), and catalysis generators.

Key properties of Inconel® 600:

- Excellent resistance in nitriding, carburizing, and oxidizing environments

- Good resistance to acids (acetic, formic, hydrofluoric, fatty acids), ammonia, chlorine, and hydrogen chloride (up to ~500°C)

- High resistance to stress corrosion cracking

- Good mechanical performance across a wide temperature range

- Stable in reducing environments

- Not hardenable

Purchase Inconel® 600 from Evek GmbH for premium nickel alloys and outstanding customer service at competitive prices.

- Type

- Round bar

- material

- Nickel alloy

- operation area

- Furnace construction; reactor construction; caustic tanks; plant components for the production of chlorine, hydrogen chloride and fluorine; automotive industry (HT sensors, rupture disks for airbags); production of vinyl chloride (reaction tanks, heat

- US

- N06600

- Alloy

- 600

- density

- 8.5 g/cm³

- Melting point

- 1370°C

- Thermal conductivity

- 14.8 W/(m-K)

- Electrical resistance

- 1.03 Ω mm²/m

You might also like

(5/5) on 4 rating(s)

£26.97

(5/5) on 4 rating(s)

£20.24

(5/5) on 4 rating(s)

£491.00

(5/5) on 6 rating(s)

£2,708.60

(5/5) on 4 rating(s)

£680.60

(5/5) on 4 rating(s)

£2,036.19

(5/5) on 5 rating(s)

£2,473.40

(5/5) on 4 rating(s)

£2,822.80

(4,8/5) on 5 rating(s)

£3,231.90

(5/5) on 4 rating(s)

£1,580.30

(5/5) on 4 rating(s)

£2,253.20

(5/5) on 4 rating(s)

£2,253.20

(5/5) on 5 rating(s)

£305.40

(5/5) on 5 rating(s)

£496.10

(5/5) on 4 rating(s)

£2,590.50

(5/5) on 4 rating(s)

£2,234.30

(5/5) on 4 rating(s)

£1,778.20

Reviews

By

blaugates165

B.

on

(Inconel® 600 Alloy rod 10-200mm 2.4816 round bar) :

(5/5)

By

breditarzan

B.

on

(Inconel® 600 Alloy rod 10-200mm 2.4816 round bar) :

(5/5)

By

casio2119

C.

on

(Inconel® 600 Alloy rod 10-200mm 2.4816 round bar) :

(5/5)

-

-

Select

Price: low-to-high

Price: high-to-low

| | Combination name | Price | |

| |

£1,596.60

|

|

|

| |

length : 1 Meter x 10 st/pc

diameter : 10mm

|

£3,193.10

|

|

| |

£2,299.00

|

|

|

| |

£1,634.90

|

|

|

| |

£2,554.50

|

|

|

| |

£1,545.10

|

|

|

| |

length : 1 Meter

diameter : 25.4mm

|

£2,060.10

|

|

| |

£1,745.80

|

|

|

| |

length : 1 Meter

diameter : 27mm

|

£2,327.80

|

|

| |

£2,155.40

|

|

|

| |

length : 1 Meter

diameter : 30mm

|

£2,873.80

|

|

| |

£1,845.60

|

|

|

| |

length : 0.75 Meter

diameter : 34mm

|

£2,768.40

|

|

| |

£1,564.60

|

|

|

| |

length : 0.5 Meter

diameter : 35mm

|

£1,955.80

|

|

| |

length : 0.75 Meter

diameter : 35mm

|

£2,933.70

|

|

| |

£1,532.70

|

|

|

| |

length : 0.4 Meter

diameter : 40mm

|

£2,043.60

|

|

| |

length : 0.5 Meter

diameter : 40mm

|

£2,554.50

|

|

| |

£1,939.80

|

|

|

| |

length : 0.4 Meter

diameter : 45mm

|

£2,586.40

|

|

| |

£1,622.20

|

|

|

| |

length : 0.3 Meter

diameter : 50.4mm

|

£2,433.30

|

|

| |

£1,931.80

|

|

|

| |

length : 0.3 Meter

diameter : 55mm

|

£2,897.80

|

|

| |

£2,299.00

|

|

|

| |

£2,698.20

|

|

|

| |

£1,564.60

|

|

|

| |

length : 0.2 Meter

diameter : 70mm

|

£3,129.30

|

|

| |

£1,854.10

|

|

|

| |

£2,043.60

|

|

|

| |

£2,586.40

|

|

|

| |

£1,596.60

|

|

|

| |

length : 0.1 Meter

diameter : 100mm

|

£3,193.10

|

|

| |

£2,111.40

|

|

|

| |

£2,698.20

|

|

|

| |

£3,129.30

|

|

|

| |

£3,592.30

|

|

|

| |

£2,069.10

|

|

|

| |

£2,554.50

|

|