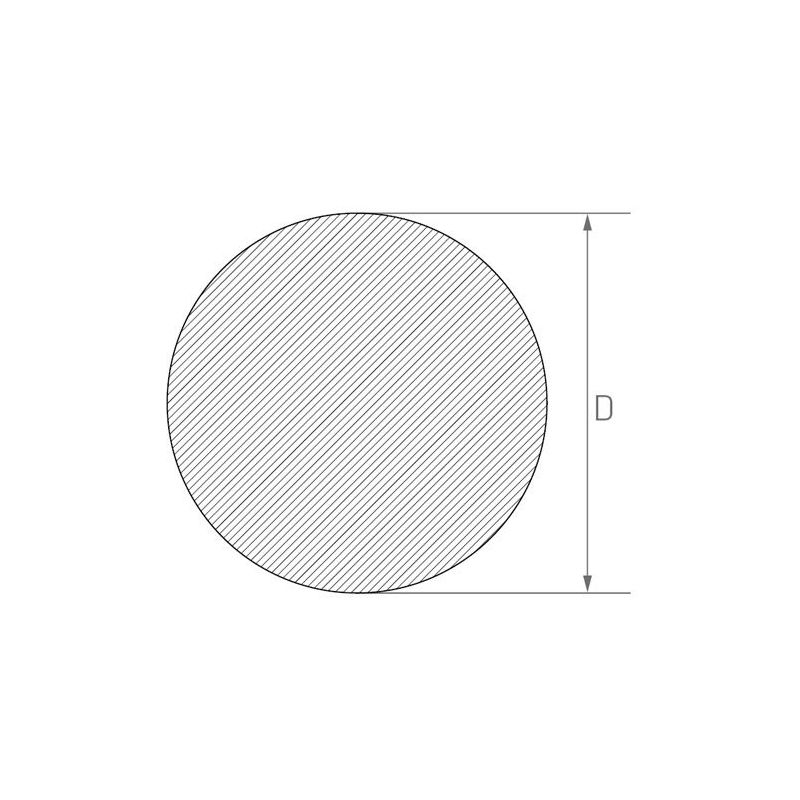

Haynes 25 bar 2.4964 Alloy L605(HS 25) Round bar 5.21-168.78mm AMS 5759 (length : 0.02 Meter, diameter : 76.71mm)

- Applications: Aerospace industry; commercial gas turbine engines; combustion chambers and afterburners; high temperature ball bearings and bearing rings.

- Properties: good ductility; excellent high temperature resistance; good resistance to oxidizing environments; good weldability.

- Do you need other steel grades or dimensions? Please contact us. Our sales team will make an offer from stock or delivery program :)

- Did you not find the desired sizes? Simply contact us! We will be happy to help you with your request

Length Tolerance +/-2mm

If you require a different steel grade or size, please reach out to us. Our sales team will provide you with a customized quote from our stock or delivery range :)

- Production time: 5–7 weeks.

- Preparation for shipping: 2–3 business days.

- Delivery time: Depends on the chosen parcel service. Please refer to our FAQ for more details.

HAYNES® 25 (UNS R30605) is a cobalt-nickel-chromium-tungsten alloy known for its outstanding high-temperature strength and excellent resistance to oxidation up to 980°C during prolonged exposure. It also resists sulfidation and offers superior wear resistance. The alloy can be processed and formed using standard manufacturing methods and is suitable for casting.

Haynes 25® is among the strongest cobalt-based alloys suitable for processing. It maintains excellent strength and oxidation resistance up to 2000 °F and is best hot-worked between 1900 °F and 2300 °F. Alloy L605 can be bent, pressed, or drawn more easily than it can be cold-formed.

The Evek GmbH Online Shop supplies material 2.4964 and offers international delivery. As a trusted supplier, we ensure safe and efficient shipping of various materials.

HAYNES® 25 is easy to form and weld. It can be forged or hot-worked after being heated to 1205°C until the entire piece reaches temperature. The alloy is also suitable for cold forming due to its good ductility.

Key properties of HAYNES® 25 include:

- High ductility;

- Exceptional resistance to high temperatures;

- Reliable resistance to oxidizing environments;

- Good weldability.

Typical applications for HAYNES® 25:

- Aerospace components;

- Commercial gas turbine engines;

- Combustion chambers and afterburners;

- High-temperature ball bearings and bearing rings.

If you are interested in purchasing material 2.4964, Evek GmbH offers competitive pricing and will provide a tailored quote if you cannot find your desired product in our selection.

- Type

- Round bar

- material

- Nickel alloy

- Material number

- 2.4964

- Alloy

- L-605

-

-

| | Combination name | Price | |

| |

£1,166.50

|

|

|

| |

£1,876.40

|

|

|

| |

£2,158.50

|

|

|

| |

length : 1 Meter

diameter : 8.18mm

|

£2,878.00

|

|

| |

£1,645.70

|

|

|

| |

length : 0.5 Meter

diameter : 9.78mm

|

£2,057.20

|

|

| |

length : 0.75 Meter

diameter : 9.78mm

|

£3,085.80

|

|

| |

£2,165.90

|

|

|

| |

length : 0.4 Meter

diameter : 12.95mm

|

£2,887.90

|

|

| |

£2,238.50

|

|

|

| |

£1,603.30

|

|

|

| |

£1,763.20

|

|

|

| |

£2,174.00

|

|

|

| |

£2,831.50

|

|

|

| |

£1,787.90

|

|

|

| |

£1,988.60

|

|

|

| |

£2,203.40

|

|

|

| |

£2,662.30

|

|

|

| |

£3,164.50

|

|

|

| |

£3,710.10

|

|

|

| |

£1,719.60

|

|

|

| |

£2,242.90

|

|

|

| |

£2,835.50

|

|

|

| |

£3,497.50

|

|

|

| |

£4,228.90

|

|

|

| |

£5,063.20

|

|

|

| |

£6,878.50

|

|

|

| |

£8,971.40

|

|

|

| |

£11,341.90

|

|