Haynes 25 bar 2.4964 Alloy L605(HS 25) Round bar 5.21-168.78mm AMS 5759 (length : 0.02 Meter, diameter : 57.40mm)

- Applications: Aerospace industry; commercial gas turbine engines; combustion chambers and afterburners; high temperature ball bearings and bearing rings.

- Properties: good ductility; excellent high temperature resistance; good resistance to oxidizing environments; good weldability.

- Do you need other steel grades or dimensions? Please contact us. Our sales team will make an offer from stock or delivery program :)

- Did you not find the desired sizes? Simply contact us! We will be happy to help you with your request

Length Tolerance +/-2mm

If you require a different steel grade or size, please contact us. Our sales team will provide you with a quote from our stock or delivery program :)

- Production time: 5-7 weeks

- Preparation for shipping: 2-3 business days

- Delivery time: Depends on the parcel service. Please refer to our FAQ.

HAYNES® 25 (UNS R30605) is a cobalt-nickel-chromium-tungsten alloy known for its outstanding resistance to high temperatures and excellent performance in oxidizing conditions up to 980°C during prolonged use. It also offers superior resistance to sulfidation and metal wear. This alloy can be easily fabricated and formed using standard methods and is suitable for casting.

Among workable cobalt alloys, Haynes 25® is the strongest. It maintains excellent strength and oxidation resistance up to 2000°F. The alloy is hot workable between 1900°F and 2300°F and is better suited for bending, pressing, and drawing than for cold forming.

Evek GmbH Online Shop supplies material 2.4964 and offers worldwide shipping. As a trusted supplier, we ensure safe and straightforward delivery of various materials.

HAYNES® 25 is easy to form and weld. It can be forged or hot worked after holding at 1205°C to ensure uniform temperature throughout the piece. Thanks to its good ductility, the alloy is also suitable for cold forming.

Key features of HAYNES® 25:

- Good ductility

- Excellent high-temperature resistance

- Outstanding resistance to oxidizing environments

- Good weldability

Typical applications for HAYNES® 25 include:

- Aerospace industry

- Commercial gas turbine engines

- Combustion chambers and afterburners

- High-temperature ball bearings and bearing rings

If you’re looking to purchase material 2.4964, Evek GmbH offers competitive prices. If you can’t find the exact product you need, feel free to request a custom offer.

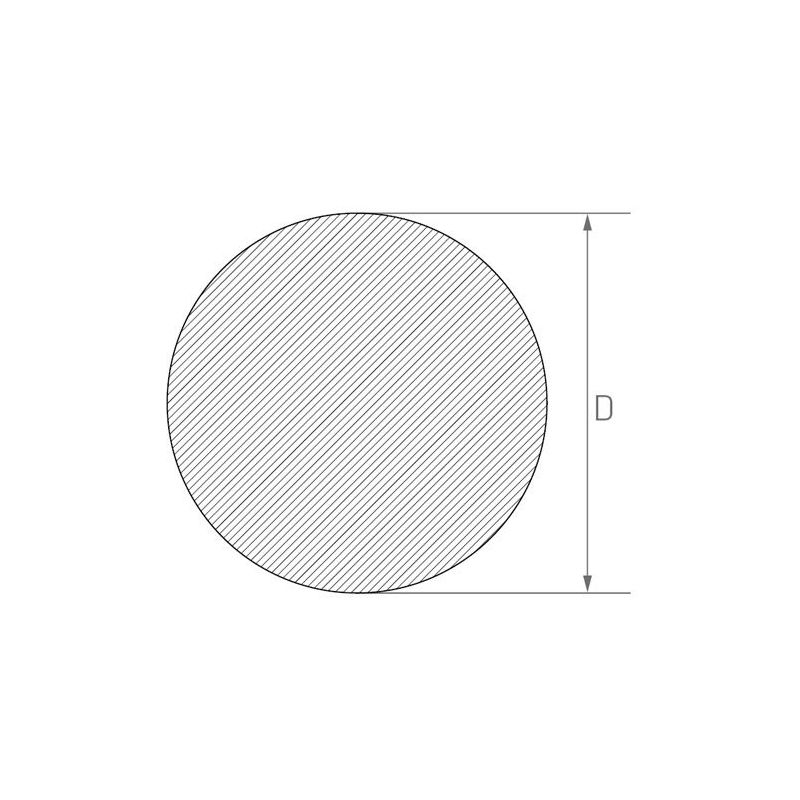

- Type

- Round bar

- material

- Nickel alloy

- Material number

- 2.4964

- Alloy

- L-605

-

-

| | Combination name | Price | |

| |

£1,166.50

|

|

|

| |

£1,876.40

|

|

|

| |

£2,158.50

|

|

|

| |

length : 1 Meter

diameter : 8.18mm

|

£2,878.00

|

|

| |

£1,645.70

|

|

|

| |

length : 0.5 Meter

diameter : 9.78mm

|

£2,057.20

|

|

| |

length : 0.75 Meter

diameter : 9.78mm

|

£3,085.80

|

|

| |

£2,165.90

|

|

|

| |

length : 0.4 Meter

diameter : 12.95mm

|

£2,887.90

|

|

| |

£2,238.50

|

|

|

| |

£1,603.30

|

|

|

| |

£1,763.20

|

|

|

| |

£2,174.00

|

|

|

| |

£2,831.50

|

|

|

| |

£1,787.90

|

|

|

| |

£1,988.60

|

|

|

| |

£2,203.40

|

|

|

| |

£2,662.30

|

|

|

| |

£3,164.50

|

|

|

| |

£3,710.10

|

|

|

| |

£1,719.60

|

|

|

| |

£2,242.90

|

|

|

| |

£2,835.50

|

|

|

| |

£3,497.50

|

|

|

| |

£4,228.90

|

|

|

| |

£5,063.20

|

|

|

| |

£6,878.50

|

|

|

| |

£8,971.40

|

|

|

| |

£11,341.90

|

|