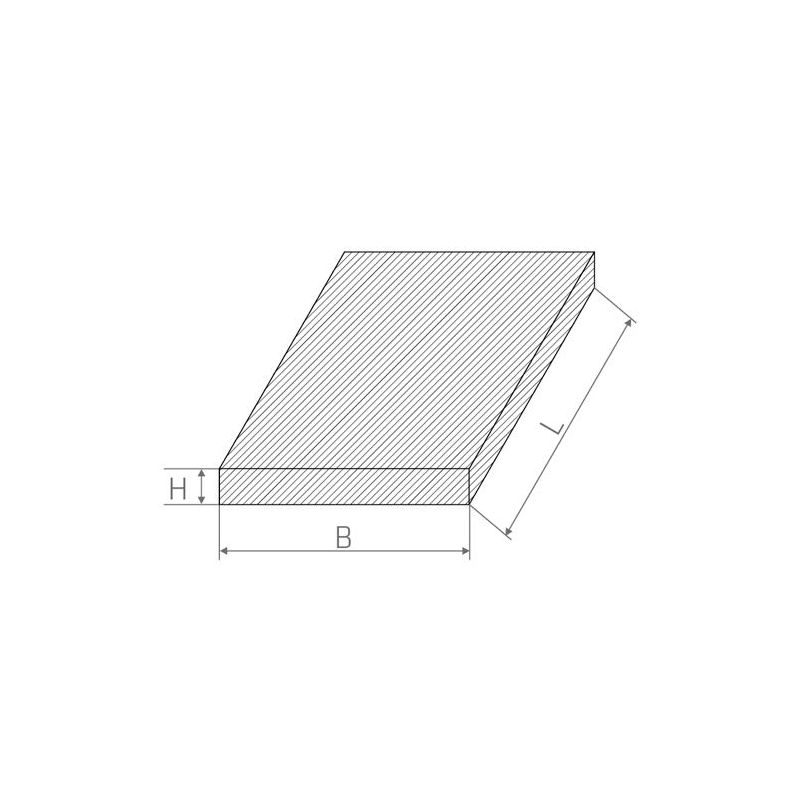

Inconel® 718 Alloy sheet 0.254-50.8mm 2.4668 Plates cut to size N07718 100-1000mm (Thickness / Strength : 6.35mm, width x length : 150x150mm)

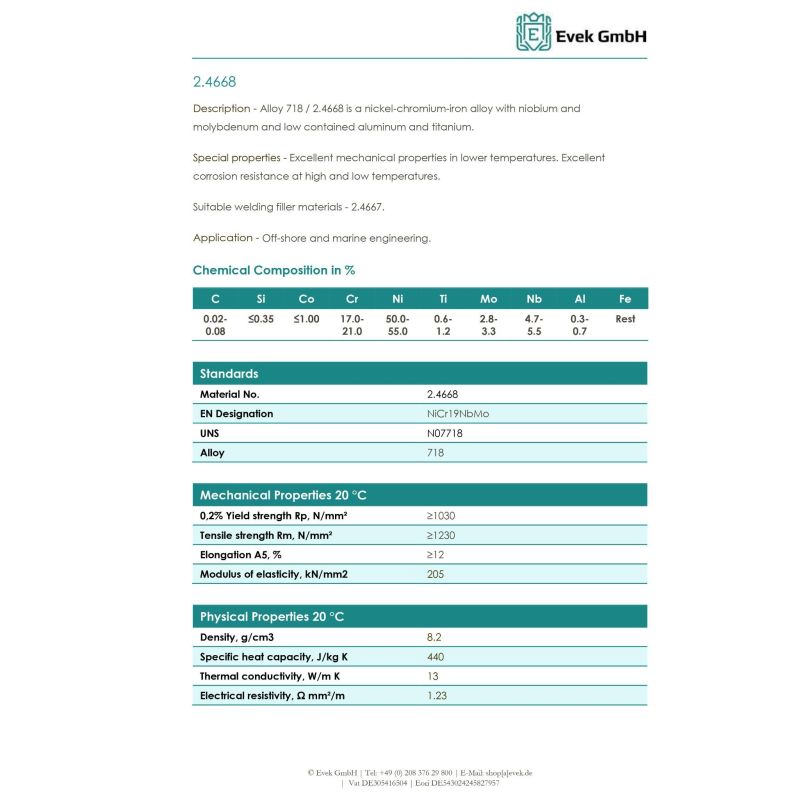

- Wnr. 2.4668; UNS N07718; Alloy 718;

- Fields of application: Aerospace (engines, gas turbines and housings); offshore engineering and marine equipment; oil and gas industry; nuclear reactors; manufacture of springs and high-strength fasteners;

- Properties: good formability and hardenability; good processing properties in solution-annealed condition; excellent corrosion resistance at high and low temperatures; insensitivity to pitting and stress corrosion cracking; very good creep rupture strength and high fatigue strength; very good weldability; good resistance to oxidation up to 1000 °C;

- Density 8.2 g/cm³; melting point 1260 °C;

- Available cut to size or made to measure.

Sheet Metal Blank Tolerances and Surface Information

Please note: Sheet metal blanks are intended for industrial use and are not recommended for decorative or visible applications, as surface scratches may occur. The finish is industrial-grade and sheets are cut with guillotine shears. Not all pieces come with a protective film. If surface quality is important for your project, please contact us for options.

If you require a different steel grade or custom dimensions, feel free to contact us. Our sales team will happily provide a tailored offer from our stock or delivery program.

- Manufacturing time: 5-7 weeks.

- Shipment preparation: 2-3 business days.

- Delivery duration: depends on the parcel service—please refer to our FAQ for details.

Inconel® 718 is a hardenable alloy primarily composed of nickel, chromium, and iron, with additional elements like niobium, molybdenum, aluminum, and titanium. The presence of niobium, titanium, and aluminum enhances its hardenability. When solution-annealed, Inconel 718 (2.4668) is easy to shape and process. The alloy stands out for its excellent corrosion resistance at both high and low temperatures, and is highly resistant to pitting and stress corrosion cracking. It also offers outstanding creep resistance, fatigue strength, weldability, and can withstand oxidation up to 1000 °C.

Purchase Inconel® 718 from Evek GmbH—your trusted supplier for premium nickel alloys, offering secure and worldwide delivery.

Inconel® 718 is widely used in the aerospace sector for manufacturing engines, gas turbines, and housing components. It is also sought after in offshore technology, marine equipment, the oil and gas industry, nuclear reactors, and for producing springs and high-strength fasteners.

Main properties of Inconel® 718 include:

- Excellent formability and hardenability

- Good processing properties in solution-annealed condition

- Superior corrosion resistance in extreme temperatures

- High resistance to pitting and stress corrosion cracking

- Outstanding creep and fatigue strength

- Very good weldability

- Effective oxidation resistance up to 1000 °C

Find competitive Inconel® 718 prices at Evek GmbH. Explore our online store for nickel alloys with worldwide shipping.

- Type

- Sheet metal

- material

- Nickel alloy

- Material number

- 2.4668

- US

- N07718

-

-

| | Combination name | Price | |

| |

£2,881.20

|

|

|

| |

Thickness / Strength : 1.016mm

width x length : 400x400mm

|

£2,305.00

|

|

| |

£1,620.70

|

|

|

| |

Thickness / Strength : 1.27mm

width x length : 400x400mm

|

£2,881.20

|

|

| |

£1,782.80

|

|

|

| |

width x length : 400x400mm

Thickness / Strength : 1.397mm

|

£3,169.30

|

|

| |

£2,042.10

|

|

|

| |

£2,105.60

|

|

|

| |

£2,654.30

|

|

|

| |

£2,922.30

|

|

|

| |

£3,241.40

|

|

|

| |

£1,797.90

|

|

|

| |

£2,104.20

|

|

|

| |

£2,290.60

|

|

|

| |

£1,515.40

|

|

|

| |

Thickness / Strength : 4.75mm

width x length : 200x200mm

|

£2,694.00

|

|

| |

£2,025.90

|

|

|

| |

Thickness / Strength : 6.35mm

width x length : 200x200mm

|

£3,601.50

|

|

| |

£2,609.00

|

|

|

| |

£3,190.30

|

|

|

| |

£1,800.80

|

|

|

| |

£1,871.70

|

|

|

| |

£2,268.70

|

|

|

| |

£2,835.80

|

|

|

| |

£3,601.50

|

|

|

| |

£4,051.00

|

|

|

| |

£5,402.30

|

|

|

| |

£7,203.00

|

|