Haynes Alloy 263 Sheet 0.81-38.1mm 2.4650 Plate N-07263 Cut to size 100-1000mm (length : 150mm, width : 150mm, Thickness / Strength : 12.7mm)

- Areas of application: Aerospace; gas turbines; chemical industry.

- Properties: high strength; good oxidation resistance; good weldability.

- Do you need other steel grades or dimensions? Please contact us. Our sales team will make an offer from stock or delivery program :)

- Did you not find the desired sizes? Simply contact us! We will be happy to help you with your request

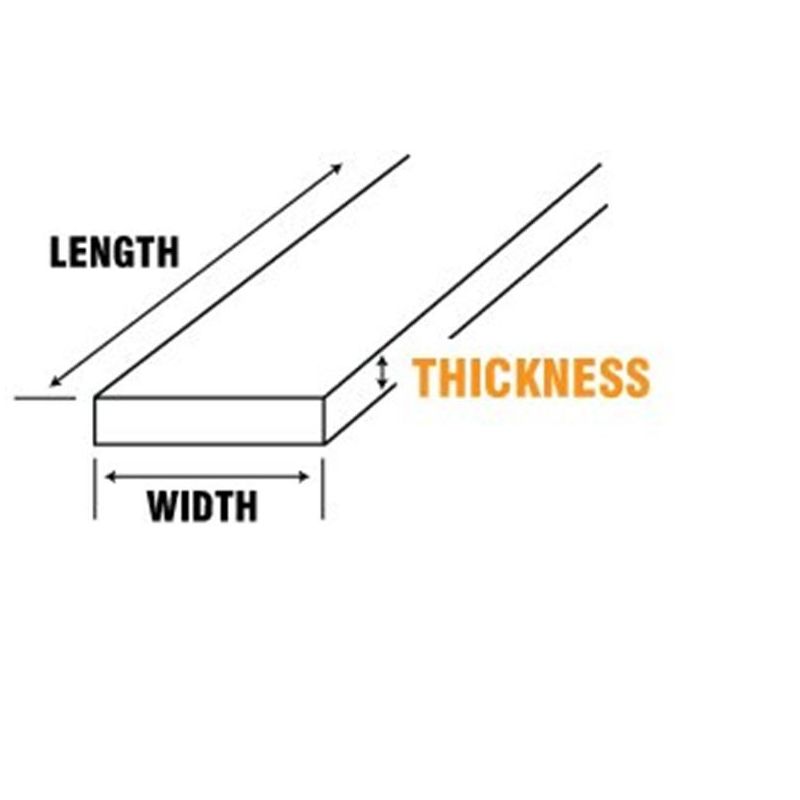

Length Tolerance +/-2mm

If you require a different steel grade or custom dimensions, please reach out to us. Our sales team will gladly provide you with an offer from our stock or delivery program.

The tolerance for both width and length of sheet metal blanks is +/-2mm. Please note: these blanks are intended for industrial use and are not suitable for decorative or visible areas, as surface scratches may be present. The surface is industrial quality and the sheets are cut with guillotine shears. Not all sheets come with protective film. If surface quality is important for your application, contact us and we will try to find a suitable solution.

- Production time: 5–7 weeks

- Shipping preparation: 2–3 business days

- Delivery time: depends on the parcel service. Please refer to the FAQ.

Haynes 263 is a nickel-cobalt-chromium-molybdenum alloy that can be age-hardened. It is designed for excellent workability in the annealed condition and high strength when age-hardened. Compared to alloys like Waspaloy or Rene 41, Haynes 263 is easier to form and weld, and maintains excellent ductility at medium temperatures. Delivered in the annealed condition, it is suitable for both cold and hot forming. Welding can be performed using TIG or MIG methods with a matching welding wire.

At Evek GmbH Online Shop, you can purchase Haynes 263 alloy with international shipping. As a trusted materials supplier, we ensure secure and straightforward delivery.

Main features of Haynes 263:

- High strength: Maintains excellent strength at both room and elevated temperatures, ideal for demanding environments.

- Oxidation resistance: Withstands temperatures up to 980°C, making it suitable for turbine and high-temperature applications.

- Weldability: Easier to weld than many other superalloys, simplifying manufacturing and repairs.

Typical applications for Haynes 263:

- Aerospace: Components like combustion chambers, thrust nozzles, and afterburners in aircraft and rocket engines.

- Gas turbines: Parts exposed to high temperatures and stress, such as turbine blades and disks.

- Chemical industry: Reactors, heat exchangers, and equipment used in corrosive and oxidizing environments.

If you are looking to purchase material 2.4650, Evek GmbH offers competitive prices and can provide a quote upon request if you do not find your desired product in our catalog.

- Type

- Sheet metal

- material

- Nickel alloy

- Material number

- 2.4650

- US

- N-07263

-

-

-

| | Combination name | Price | |

| |

£1,911.10

|

|

|

| |

£1,911.10

|

|

|

| |

length : 400mm

width : 400mm

Thickness / Strength : 1.27mm

|

£1,528.90

|

|

| |

length : 500mm

width : 500mm

Thickness / Strength : 1.27mm

|

£2,388.90

|

|

| |

£2,408.00

|

|

|

| |

length : 400mm

width : 400mm

Thickness / Strength : 1.6mm

|

£1,926.40

|

|

| |

length : 500mm

width : 500mm

Thickness / Strength : 1.6mm

|

£3,010.00

|

|

| |

£2,981.30

|

|

|

| |

length : 400mm

width : 400mm

Thickness / Strength : 1.98mm

|

£2,385.00

|

|

| |

£2,150.00

|

|

|

| |

£3,215.80

|

|

|

| |

£1,911.10

|

|

|

| |

£1,612.50

|

|

|

| |

length : 200mm

width : 200mm

Thickness / Strength : 9.53mm

|

£2,866.60

|

|

| |

£2,150.00

|

|

|

| |

£3,225.00

|

|

|

| |

£1,911.10

|

|

|

| |

£2,388.90

|

|

|

| |

£2,866.60

|

|