- Type Welding...

- material Titanium

- operation area Joint...

- Material number 3.7035

- AWS A 5.16: ER Ti 2

There are 30 products.

Welding wire Hastelloy® C22 Nickel 2.4602 Ø 0.8-5mm TIG TIG welding...

Last items in stock

£49.41

- Type Welding...

- material Nickel alloy

- Material number 2.4602

- Alloy 22

- Stretch limit 300 N/mm²

- Type Welding...

- material Nickel alloy

- Material number 2.4649

- Alloy 625

- tensile strenght 760 N/mm²

Welding electrodes Inconel 718 Nickel 2.4668 Ø 0.8-5mm Welding wire...

Last items in stock

£7.08

Pernifer® S 36 NB TI 1.3990 alloy 36 Welding wire 1-1.6mm K93600...

Last items in stock

£2,548.00

- Type Welding rod

- material Nickel alloy

- tensile strenght 500 N/mm²

- Stretch limit 350 N/mm²

- Elongation at break 20 %

Welding wire 2.4607 NiCrMo13 Nickel Ø 1.6-3.2mm TIG TIG welding...

Last items in stock

£1,500.00

- Type Welding...

- material Nickel alloy

Welding wire Hastelloy® C276 Nickel 2.4886 Ø 1.6-3.2mm TIG TIG...

Last items in stock

£2,548.00

- Type Welding...

- material Nickel alloy

- Alloy C-276

- tensile strenght 750 N/mm²

- Stretch limit 450 N/mm²

Nife® S 6040 2.4560 alloy welding wire 0.8-1.6mm nickel alloy

Last items in stock

£1,769.20

- material Nickel alloy

- Material number 2.4560

- tensile strenght 350 N/mm²

- Stretch limit 250 N/mm²

- Elongation at break 6%

Nicrofer® S 6025 2.4649 alloy 602CA Welding wire 0.8-1.6mm N06025...

Last items in stock

£3,242.30

- Type Welding rod

- material Nickel alloy

- Material number 2.4649

- US N06025

- tensile strenght 650 N/mm²

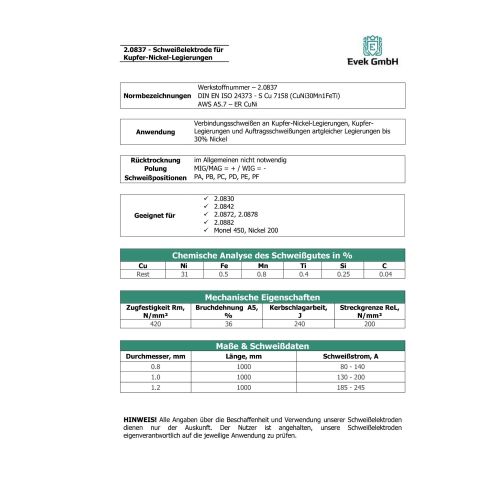

Welding wire Monel® 67 Nickel 2.0837 Ø 1.6-3.2mm TIG TIG welding...

Last items in stock

£1,764.00

- Type Welding...

- material Nickel alloy

- Alloy 67

- tensile strenght 420 N/mm²

- Stretch limit 200 N/mm²

Welding wire Monel® 60 Nickel 2.4377 Ø 1.6-2.4mm TIG TIG welding...

Last items in stock

£2,156.00

- Type Welding...

- material Nickel alloy

- US N04060

- Alloy 60

- tensile strenght 450 N/mm²

Welding wire 1.4591 Alloy 33 Ø 2-2.4mm TIG welding rods Nicrofer® 3033

Last items in stock

£2,156.00

- Type Welding...

- material Nickel alloy

- Material number 1.4591

- US R20033

- tensile strenght 750 N/mm²

Welding wire 2.4649 NiCrFe-12 Nickel Ø 1.6-3.2mm TIG TIG welding...

Last items in stock

£1,500.00

- Type Welding...

- material Nickel alloy

- tensile strenght 650 N/mm²

- Stretch limit 300 N/mm²

- Elongation at break 25%

FAQ

❤ What products from Welding and soldering category available in Evek Shop online store

A wide range of products is presented in the category Welding and soldering.

Today the leaders in this segment are:

✓ Welding electrodes Titanium 3.7035 Grade 2 Ø 0.8-5mm AWS ERTi 2 Titanium welding rod

✓ Welding wire Hastelloy® C22 Nickel 2.4602 Ø 0.8-5mm TIG TIG welding rods Alloy 22

✓ Welding wire Inconel® 625 Nickel 2.4831 Ø 0.8-5mm TIG TIG welding rods NiCrMo-3

✓ Welding wire 1.4430 VA V4A 316 stainless steel Ø 0.8-5mm TIG TIG welding rods INOX NIRO

✓ Welding wire 1.4551 VA V2A 347 stainless steel Ø 1-5mm TIG TIG welding rods INOX NIRO

Today the leaders in this segment are:

✓ Welding electrodes Titanium 3.7035 Grade 2 Ø 0.8-5mm AWS ERTi 2 Titanium welding rod

✓ Welding wire Hastelloy® C22 Nickel 2.4602 Ø 0.8-5mm TIG TIG welding rods Alloy 22

✓ Welding wire Inconel® 625 Nickel 2.4831 Ø 0.8-5mm TIG TIG welding rods NiCrMo-3

✓ Welding wire 1.4430 VA V4A 316 stainless steel Ø 0.8-5mm TIG TIG welding rods INOX NIRO

✓ Welding wire 1.4551 VA V2A 347 stainless steel Ø 1-5mm TIG TIG welding rods INOX NIRO

❤ Welding and soldering - what products are popular and sold?

TOP 5 most popular products in Welding and soldering category in Evek Shop in terms of price-quality ratio:

✓ Welding wire 1.4551 VA V2A 347 stainless steel Ø 1-5mm TIG TIG welding rods INOX NIRO

✓ Welding electrodes 904L stainless steel TIG 1.4519 Ø 0.8-5mm welding rod Welding rods

✓ Welding electrodes Inconel 718 Nickel 2.4668 Ø 0.8-5mm Welding wire Welding rods

✓ Welding electrodes Titanium 3.7035 Grade 2 Ø 0.8-5mm AWS ERTi 2 Titanium welding rod

✓ Welding wire Inconel® 625 Nickel 2.4831 Ø 0.8-5mm TIG TIG welding rods NiCrMo-3

✓ Welding wire 1.4551 VA V2A 347 stainless steel Ø 1-5mm TIG TIG welding rods INOX NIRO

✓ Welding electrodes 904L stainless steel TIG 1.4519 Ø 0.8-5mm welding rod Welding rods

✓ Welding electrodes Inconel 718 Nickel 2.4668 Ø 0.8-5mm Welding wire Welding rods

✓ Welding electrodes Titanium 3.7035 Grade 2 Ø 0.8-5mm AWS ERTi 2 Titanium welding rod

✓ Welding wire Inconel® 625 Nickel 2.4831 Ø 0.8-5mm TIG TIG welding rods NiCrMo-3

❤ How is the delivery of goods from Welding and soldering category?

All shipping information is available on the page Shipping.

❤ What discounts does Evek Shop offer for Welding and soldering buyers?

All relevant information regarding the discount program is presented on the page Discount.