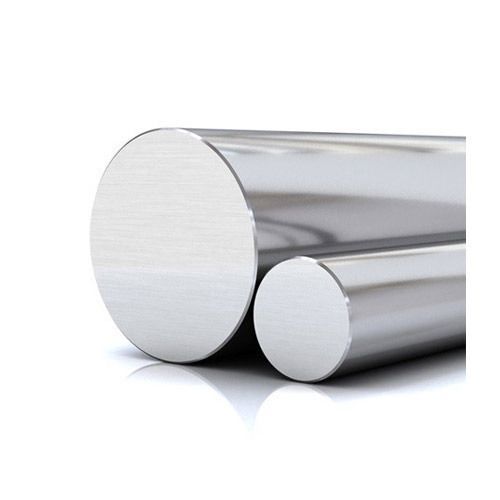

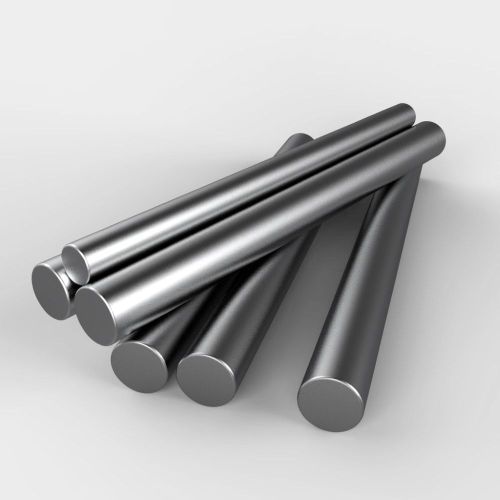

Inconel® Alloy c22 Rod 12.7-230mm Round rod 2.4602 Hastelloy® (length : 1 Meter x 5 st/pc, diameter : 12.7mm)

- Do you need a different steel quality or dimensions? Please contact us. Our sales team will make you an offer from our stock program or delivery program :)

- Cuts from 100mm to 1000mm, thicknesses from 12.7 mm and up to 165.1 mm

- Areas of application: chemical industry; acetic acid production; environmental technology (waste water plants, waste incineration plants); pharmaceutical industry; waste incineration plants; pulp or paper industry; heat exchangers;

- Didn't find the sizes you were looking for? Simply contact us! We will be happy to help you with your request

Customer ratings and reviews

Durchschnittliche Bewertung

5

review(s): 4

- 4

- 0

- 0

- 0

- 0

Length tolerance: +/-2mm

- Production time: 5-7 weeks

- Shipment preparation: 2-3 business days

- Delivery time: Depends on the shipping provider (see FAQ for details)

Alloy 2.4602, also known as Hastelloy® C22, is a highly corrosion-resistant material made from nickel, molybdenum, chromium, and tungsten, with very low levels of carbon and silicon. It offers outstanding resistance in both oxidizing and reducing environments, even at high temperatures. This alloy is particularly resistant to oxidizing and mineral acids such as sulfuric, phosphoric, and nitric acids, as well as to chlorine gas and acid mixtures containing sulfuric acid. It also demonstrates excellent resistance to crevice corrosion, stress corrosion cracking, and pitting at elevated temperatures. Alloy C22 is suitable for both cold and hot forming processes.

Evek GmbH supplies 2.4602 worldwide and is a trusted source for nickel alloys. For inquiries, please contact us.

Thanks to its superior resistance to mineral acids, Hastelloy® C22 is widely used in the chemical industry, including in acetic acid production reactors. Other common applications include:

- Environmental technology (wastewater treatment and waste incineration plants)

- Pharmaceutical industry

- Pulp and paper industry

- Heat exchangers

Key features of Alloy C22 include:

- Excellent resistance in oxidizing and reducing environments

- Superior resistance to oxidizing and mineral acids

- High resistance to crevice, stress corrosion, and pitting at high temperatures

- Durable against chlorine gas and acid mixtures with sulfuric acid

- Good formability in both cold and hot conditions

- Type

- Round bar

- material

- Nickel alloy

- operation area

- Chemical industry; acetic acid production; environmental technology (waste water plants, waste incineration plants); pharmaceutical industry; waste incineration plants; pulp or paper industry; heat exchangers

- US

- 06022

- density

- 8.7 g/cm³

- Melting point

- 1355 °C

- Thermal conductivity

- 9.6 W/(m - K)

- Electrical resistance

- 1.14 Ω mm²/m

You might also like

(5/5) on 4 rating(s)

kr16,883.20

(5/5) on 6 rating(s)

kr24,139.49

(5/5) on 4 rating(s)

kr27,969.82

(3,8/5) on 4 rating(s)

kr16,370.30

(5/5) on 4 rating(s)

kr17,289.60

(5/5) on 4 rating(s)

kr14,229.16

(5/5) on 4 rating(s)

kr240.36

(5/5) on 5 rating(s)

kr22,043.35

(5/5) on 5 rating(s)

kr34,788.63

(5/5) on 4 rating(s)

kr18,668.31

(4,8/5) on 5 rating(s)

kr17,548.05

(5/5) on 4 rating(s)

kr73,970.07

(5/5) on 5 rating(s)

kr17,921.47

(5/5) on 4 rating(s)

kr25,157.26

(4,8/5) on 5 rating(s)

kr28,803.22

(5/5) on 4 rating(s)

kr35,812.64

(5/5) on 4 rating(s)

kr20,080.89

(4,8/5) on 4 rating(s)

kr14,343.24

(5/5) on 4 rating(s)

kr6.24

(5/5) on 4 rating(s)

kr6.77

Reviews

By

2451erich

2.

on

(Inconel® Alloy c22 Rod 12.7-230mm Round rod 2.4602 Hastelloy®) :

(5/5)

It's all ok! I just thought th...

It's all ok! I just thought that the 10g are in one piece.

Report abuse

By

heinzs04

H.

on

(Inconel® Alloy c22 Rod 12.7-230mm Round rod 2.4602 Hastelloy®) :

(5/5)

By

petroviz2511

P.

on

(Inconel® Alloy c22 Rod 12.7-230mm Round rod 2.4602 Hastelloy®) :

(5/5)

-

-

Select

Price: low-to-high

Price: high-to-low

| | Combination name | Price | |

| |

kr20,080.89

|

|

|

| |

kr31,872.57

|

|

|

| |

kr19,920.47

|

|

|

| |

kr15,562.42

|

|

|

| |

length : 1 Meter x 2 st/pc

diameter : 25mm

|

kr31,125.73

|

|

| |

kr16,065.07

|

|

|

| |

length : 1 Meter x 2 st/pc

diameter : 25.4mm

|

kr32,129.24

|

|

| |

kr16,807.45

|

|

|

| |

length : 1 Meter

diameter : 30mm

|

kr22,410.53

|

|

| |

kr18,826.06

|

|

|

| |

length : 1 Meter

diameter : 31.75mm

|

kr25,101.11

|

|

| |

kr15,251.39

|

|

|

| |

length : 0.75 Meter

diameter : 35mm

|

kr22,877.52

|

|

| |

kr14,458.20

|

|

|

| |

length : 0.5 Meter

diameter : 38.1mm

|

kr18,072.98

|

|

| |

length : 0.75 Meter

diameter : 38.1mm

|

kr27,109.02

|

|

| |

kr15,935.84

|

|

|

| |

length : 0.5 Meter

diameter : 40mm

|

kr19,920.47

|

|

| |

kr15,126.62

|

|

|

| |

length : 0.4 Meter

diameter : 45mm

|

kr20,169.12

|

|

| |

length : 0.5 Meter

diameter : 45mm

|

kr25,211.62

|

|

| |

kr18,675.44

|

|

|

| |

length : 0.4 Meter

diameter : 50mm

|

kr24,900.59

|

|

| |

kr19,277.90

|

|

|

| |

length : 0.4 Meter

diameter : 50.8mm

|

kr25,703.57

|

|

| |

kr16,265.59

|

|

|

| |

length : 0.3 Meter

diameter : 57.15mm

|

kr24,397.94

|

|

| |

kr17,928.60

|

|

|

| |

length : 0.3 Meter

diameter : 60mm

|

kr26,892.45

|

|

| |

kr20,080.89

|

|

|

| |

kr24,402.40

|

|

|

| |

kr16,968.76

|

|

|

| |

kr20,169.12

|

|

|

| |

kr25,703.57

|

|

|

| |

kr16,465.22

|

|

|

| |

kr21,040.73

|

|

|

| |

kr24,402.40

|

|

|

| |

kr28,012.71

|

|

|

| |

kr13,575.01

|

|

|

| |

kr26,344.36

|

|