Inconel® 2.4819 Alloy c276 Wire 0.8-1.6mm Hastelloy® N010276 Nickel alloy (size : 0.8mm, length : 2500 Meter (11.2kg))

- Areas of application: chemical industry; pulp and paper industry; acetic acid production; crude oil and natural gas production; processing and production of contaminated phosphoric acid; waste incineration plants;

- Properties: Resistance to chloride ion attack; high resistance to many corrosive media under oxidizing and reducing conditions;

- Density 8.6 g/cm³; Melting point 1325 °C; Elongation at break 3-5%

- Didn't find the sizes you were looking for? Simply contact us! We will be happy to help you with your request.

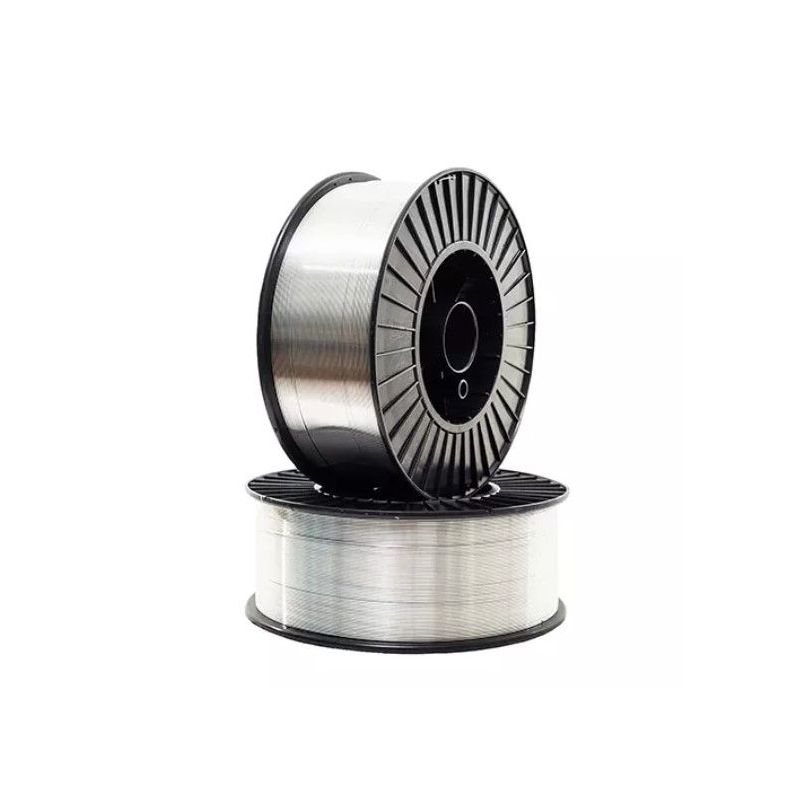

Please note: The wire is typically supplied on a spool, but in some cases may be delivered as a coil (ring) without a spool. If you specifically require a spool, please confirm before placing your order.

If you need a different steel grade or size, feel free to reach out to us. Our sales team will be happy to provide you with a customized offer from stock or our delivery program :)

- Manufacturing time: 2-3 weeks

- Order preparation: 2-3 business days

- Shipping duration: Depends on the parcel service. Please refer to our FAQ for more details.

2.4819, also known as Alloy C276, is a nickel-chromium-molybdenum alloy with added tungsten. Thanks to its high chromium and molybdenum content, it offers outstanding resistance to chloride ion attack, further enhanced by the presence of tungsten. Featuring very low carbon and silicon levels, this alloy is highly resistant to many corrosive environments, both oxidizing and reducing. Alloy C276 is extremely resistant to pitting, crevice corrosion, and stress corrosion cracking. It is suitable for both cold and hot forming processes and can be welded using all standard methods.

2.4819 is competitively priced and available in our online store, which offers a broad selection of high-quality nickel alloys. Your satisfaction is our top priority.

Because of its exceptional resistance to mineral and organic acids and solutions, Alloy C276 is predominantly used in the chemical industry. Other applications include:

- Pulp and paper manufacturing

- Acetic acid production

- Oil and natural gas extraction

- Processing and production of contaminated phosphoric acid

- Waste incineration facilities

Key characteristics of Hastelloy® C276:

- Highly resistant to chloride ion attack

- Superior resistance in many corrosive environments, both oxidizing and reducing

- Outstanding resistance to pitting, crevice, and stress corrosion cracking

- Excellent suitability for cold and hot forming

- Good weldability

Purchase 2.4819 from Evek GmbH, your trusted supplier. We ensure fast, safe, and straightforward worldwide deliveries, and guarantee the highest quality for all our nickel alloys.

- Type

- Wire

- material

- Nickel alloy

- Melting point

- 1325 °C

- Thermal conductivity

- 10.6 W/(m - K)

- Electrical resistance

- 1.25 Ω mm²/m