Inconel X-750 rod 2.4669 low-friction ams 5698 99, uns N07750, astm B 637 (length : 0.1 Meter, diameter : 42mm)

- Do you need a different steel quality or dimension? Please write to us. Our sales team makes an offer from stock program or delivery program :)

- Areas of application: components for gas turbines; combustion chamber of rocket engines; highly heat-resistant springs, screws and fasteners (up to 650 °C)

- Didn't find the sizes you wanted? Just contact us! We are happy to help you with your request

Length tolerance: +/-2mm

If you need a different steel grade or size, please contact us. Our sales team will provide you with an offer from our stock or delivery program.

- Manufacturing time: 2-3 business days.

- Preparation for shipping: 2-3 business days.

- Delivery time: depends on the shipping service. Please refer to our FAQ.

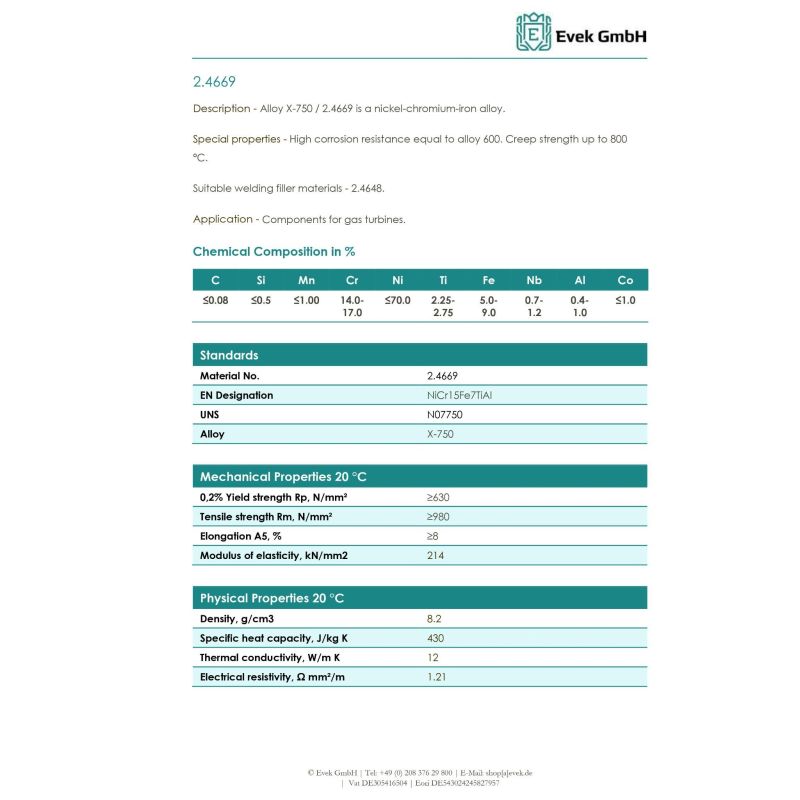

2.4669 is a nickel-chromium-iron alloy that can be hardened. It contains about 70% nickel and 15% chromium, with iron (approx. 7%) and titanium (approx. 2.5%) as main alloying elements. In addition, aluminum, niobium, cobalt, and manganese together make up about 4%. Alloy X-750 offers excellent resistance to corrosion and oxidation, and maintains high strength at temperatures up to 700°C.

Evek GmbH is your trusted supplier for 2.4669. Purchase high-quality nickel alloys at competitive prices.

Alloy X-750 is primarily used for gas turbine components and is also suitable for:

- rocket engine combustion chambers;

- heat-resistant springs, screws, and fasteners (up to 650°C).

Key properties of 2.4669 include:

- resistance to corrosion and oxidation;

- high creep and heat resistance;

- excellent relaxation resistance.

You can find Alloy X-750 in the Evek GmbH Online Shop, along with other nickel alloys at attractive prices.

- Type

- Round bar

- material

- Nickel alloy

- Alloy

- X-750

- density

- 8.28 g/cm³

- Thermal conductivity

- 12 W/(m-K)

- Electrical resistance

- 1.21 Ω mm²/m

-

-

| | Combination name | Price | |

| |

£228.84

|

|

|

| |

length : 0.2 Meter

diameter : 24mm

|

£411.92

|

|

| |

length : 0.3 Meter

diameter : 24mm

|

£549.22

|

|

| |

length : 0.4 Meter

diameter : 24mm

|

£701.78

|

|

| |

length : 0.5 Meter

diameter : 24mm

|

£839.09

|

|

| |

length : 0.75 Meter

diameter : 24mm

|

£1,201.42

|

|

| |

length : 1 Meter

diameter : 24mm

|

£1,525.61

|

|

| |

£289.63

|

|

|

| |

length : 0.2 Meter

diameter : 27mm

|

£521.34

|

|

| |

length : 0.3 Meter

diameter : 27mm

|

£695.11

|

|

| |

length : 0.4 Meter

diameter : 27mm

|

£888.19

|

|

| |

length : 0.5 Meter

diameter : 27mm

|

£1,061.97

|

|

| |

length : 0.75 Meter

diameter : 27mm

|

£1,520.55

|

|

| |

length : 1 Meter

diameter : 27mm

|

£1,930.86

|

|

| |

£322.71

|

|

|

| |

length : 0.2 Meter

diameter : 28.5mm

|

£580.87

|

|

| |

length : 0.3 Meter

diameter : 28.5mm

|

£774.49

|

|

| |

length : 0.4 Meter

diameter : 28.5mm

|

£989.62

|

|

| |

length : 0.5 Meter

diameter : 28.5mm

|

£1,183.24

|

|

| |

length : 0.75 Meter

diameter : 28.5mm

|

£1,694.19

|

|

| |

length : 1 Meter

diameter : 28.5mm

|

£2,151.36

|

|

| |

£357.56

|

|

|

| |

length : 0.2 Meter

diameter : 30mm

|

£643.62

|

|

| |

length : 0.3 Meter

diameter : 30mm

|

£858.16

|

|

| |

length : 0.4 Meter

diameter : 30mm

|

£1,096.54

|

|

| |

length : 0.5 Meter

diameter : 30mm

|

£1,311.08

|

|

| |

length : 0.75 Meter

diameter : 30mm

|

£1,877.23

|

|

| |

length : 1 Meter

diameter : 30mm

|

£2,383.77

|

|

| |

£432.66

|

|

|

| |

length : 0.2 Meter

diameter : 33mm

|

£778.78

|

|

| |

length : 0.3 Meter

diameter : 33mm

|

£1,038.37

|

|

| |

length : 0.4 Meter

diameter : 33mm

|

£1,326.81

|

|

| |

length : 0.5 Meter

diameter : 33mm

|

£1,586.40

|

|

| |

length : 0.75 Meter

diameter : 33mm

|

£2,271.44

|

|

| |

length : 1 Meter

diameter : 33mm

|

£2,884.37

|

|

| |

£459.28

|

|

|

| |

length : 0.2 Meter

diameter : 34mm

|

£826.69

|

|

| |

length : 0.3 Meter

diameter : 34mm

|

£1,102.26

|

|

| |

length : 0.4 Meter

diameter : 34mm

|

£1,408.44

|

|

| |

length : 0.5 Meter

diameter : 34mm

|

£1,684.01

|

|

| |

length : 0.75 Meter

diameter : 34mm

|

£2,411.19

|

|

| |

length : 1 Meter

diameter : 34mm

|

£3,061.82

|

|

| |

£486.69

|

|

|

| |

length : 0.2 Meter

diameter : 35mm

|

£876.03

|

|

| |

length : 0.3 Meter

diameter : 35mm

|

£1,168.05

|

|

| |

length : 0.4 Meter

diameter : 35mm

|

£1,492.50

|

|

| |

length : 0.5 Meter

diameter : 35mm

|

£1,784.52

|

|

| |

length : 0.75 Meter

diameter : 35mm

|

£2,555.11

|

|

| |

length : 1 Meter

diameter : 35mm

|

£3,244.58

|

|

| |

£514.90

|

|

|

| |

length : 0.2 Meter

diameter : 36mm

|

£926.82

|

|

| |

length : 0.3 Meter

diameter : 36mm

|

£1,235.75

|

|

| |

length : 0.4 Meter

diameter : 36mm

|

£1,579.02

|

|

| |

length : 0.5 Meter

diameter : 36mm

|

£1,887.95

|

|

| |

length : 0.75 Meter

diameter : 36mm

|

£2,703.20

|

|

| |

length : 1 Meter

diameter : 36mm

|

£3,432.64

|

|

| |

£604.29

|

|

|

| |

length : 0.2 Meter

diameter : 39mm

|

£1,087.71

|

|

| |

length : 0.3 Meter

diameter : 39mm

|

£1,450.29

|

|

| |

length : 0.4 Meter

diameter : 39mm

|

£1,853.15

|

|

| |

length : 0.5 Meter

diameter : 39mm

|

£2,215.72

|

|

| |

length : 0.75 Meter

diameter : 39mm

|

£3,172.50

|

|

| |

length : 1 Meter

diameter : 39mm

|

£4,028.58

|

|

| |

£635.67

|

|

|

| |

length : 0.2 Meter

diameter : 40mm

|

£1,144.21

|

|

| |

length : 0.3 Meter

diameter : 40mm

|

£1,525.61

|

|

| |

length : 0.4 Meter

diameter : 40mm

|

£1,949.39

|

|

| |

length : 0.5 Meter

diameter : 40mm

|

£2,330.81

|

|

| |

length : 0.75 Meter

diameter : 40mm

|

£3,337.29

|

|

| |

length : 1 Meter

diameter : 40mm

|

£4,237.82

|

|

| |

£700.83

|

|

|

| |

length : 0.2 Meter

diameter : 42mm

|

£1,261.50

|

|

| |

length : 0.3 Meter

diameter : 42mm

|

£1,681.99

|

|

| |

length : 0.4 Meter

diameter : 42mm

|

£2,149.21

|

|

| |

length : 0.5 Meter

diameter : 42mm

|

£2,569.71

|

|

| |

length : 0.75 Meter

diameter : 42mm

|

£3,679.36

|

|

| |

length : 1 Meter

diameter : 42mm

|

£4,672.20

|

|

| |

£769.17

|

|

|

| |

length : 0.2 Meter

diameter : 44mm

|

£1,384.50

|

|

| |

length : 0.3 Meter

diameter : 44mm

|

£1,846.00

|

|

| |

length : 0.4 Meter

diameter : 44mm

|

£2,358.77

|

|

| |

length : 0.5 Meter

diameter : 44mm

|

£2,820.27

|

|

| |

length : 0.75 Meter

diameter : 44mm

|

£4,038.12

|

|

| |

length : 1 Meter

diameter : 44mm

|

£5,127.76

|

|