Inconel X-750 rod 2.4669 low-friction ams 5698 99, uns N07750, astm B 637 (length : 0.1 Meter, diameter : 40mm)

- Do you need a different steel quality or dimension? Please write to us. Our sales team makes an offer from stock program or delivery program :)

- Areas of application: components for gas turbines; combustion chamber of rocket engines; highly heat-resistant springs, screws and fasteners (up to 650 °C)

- Didn't find the sizes you wanted? Just contact us! We are happy to help you with your request

Length tolerance: +/-2mm

If you require a different steel grade or size, please contact us. Our sales team will provide a tailored quote from our stock or delivery options.

- Production time: 2-3 business days.

- Preparation for shipping: 2-3 business days.

- Delivery time: depends on the parcel service. Please refer to our FAQ for more details.

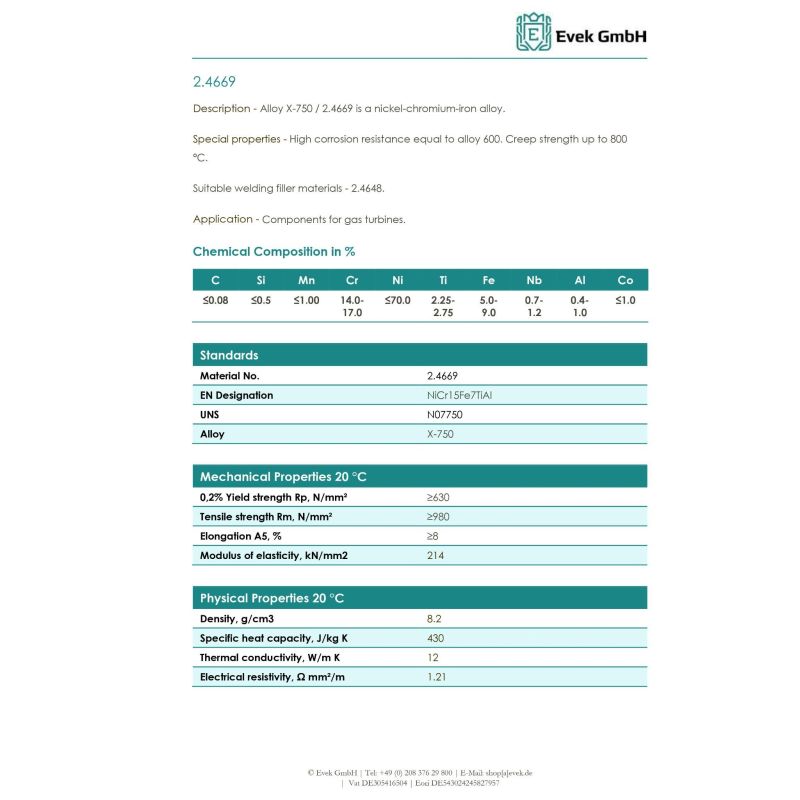

2.4669 is a nickel-chromium-iron alloy that can be hardened. It contains about 70% nickel, 15% chromium, 7% iron, and 2.5% titanium, with a combined 4% of aluminium, niobium, cobalt, and manganese. Known as Alloy X-750, this material offers excellent resistance to corrosion and oxidation, along with high strength at temperatures up to 700°C.

Evek GmbH is your trusted source for 2.4669. Purchase high-quality nickel alloys at competitive prices.

Alloy X-750 is primarily used for manufacturing gas turbine components, but is also suitable for:

- Rocket engine combustion chambers;

- Springs, screws, and fasteners that must withstand high temperatures (up to 650°C).

Key properties of 2.4669 include:

- Excellent resistance to corrosion and oxidation;

- High creep strength and heat resistance;

- Very good relaxation resistance.

Alloy X-750 is available in the Evek GmbH online store. Explore our range of nickel alloys at attractive prices.

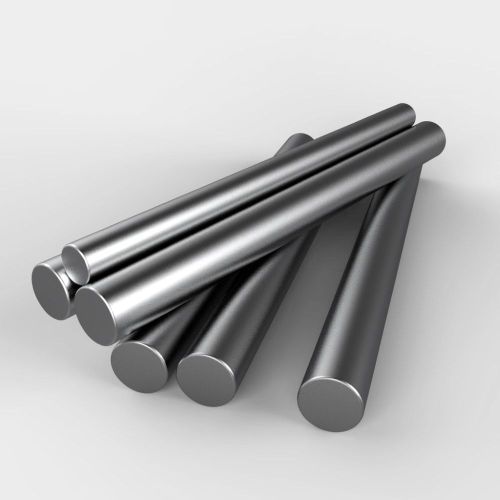

- Type

- Round bar

- material

- Nickel alloy

- Alloy

- X-750

- density

- 8.28 g/cm³

- Thermal conductivity

- 12 W/(m-K)

- Electrical resistance

- 1.21 Ω mm²/m

-

-

| | Combination name | Price | |

| |

kr3,206.11

|

|

|

| |

length : 0.2 Meter

diameter : 24mm

|

kr5,771.10

|

|

| |

length : 0.3 Meter

diameter : 24mm

|

kr7,694.71

|

|

| |

length : 0.4 Meter

diameter : 24mm

|

kr9,832.11

|

|

| |

length : 0.5 Meter

diameter : 24mm

|

kr11,755.86

|

|

| |

length : 0.75 Meter

diameter : 24mm

|

kr16,832.20

|

|

| |

length : 1 Meter

diameter : 24mm

|

kr21,374.18

|

|

| |

kr4,057.79

|

|

|

| |

length : 0.2 Meter

diameter : 27mm

|

kr7,304.10

|

|

| |

length : 0.3 Meter

diameter : 27mm

|

kr9,738.67

|

|

| |

length : 0.4 Meter

diameter : 27mm

|

kr12,443.77

|

|

| |

length : 0.5 Meter

diameter : 27mm

|

kr14,878.47

|

|

| |

length : 0.75 Meter

diameter : 27mm

|

kr21,303.29

|

|

| |

length : 1 Meter

diameter : 27mm

|

kr27,051.84

|

|

| |

kr4,521.25

|

|

|

| |

length : 0.2 Meter

diameter : 28.5mm

|

kr8,138.14

|

|

| |

length : 0.3 Meter

diameter : 28.5mm

|

kr10,850.80

|

|

| |

length : 0.4 Meter

diameter : 28.5mm

|

kr13,864.83

|

|

| |

length : 0.5 Meter

diameter : 28.5mm

|

kr16,577.49

|

|

| |

length : 0.75 Meter

diameter : 28.5mm

|

kr23,736.03

|

|

| |

length : 1 Meter

diameter : 28.5mm

|

kr30,141.10

|

|

| |

kr5,009.51

|

|

|

| |

length : 0.2 Meter

diameter : 30mm

|

kr9,017.28

|

|

| |

length : 0.3 Meter

diameter : 30mm

|

kr12,023.04

|

|

| |

length : 0.4 Meter

diameter : 30mm

|

kr15,362.80

|

|

| |

length : 0.5 Meter

diameter : 30mm

|

kr18,368.56

|

|

| |

length : 0.75 Meter

diameter : 30mm

|

kr26,300.47

|

|

| |

length : 1 Meter

diameter : 30mm

|

kr33,397.22

|

|

| |

kr6,061.68

|

|

|

| |

length : 0.2 Meter

diameter : 33mm

|

kr10,910.90

|

|

| |

length : 0.3 Meter

diameter : 33mm

|

kr14,547.83

|

|

| |

length : 0.4 Meter

diameter : 33mm

|

kr18,588.94

|

|

| |

length : 0.5 Meter

diameter : 33mm

|

kr22,225.86

|

|

| |

length : 0.75 Meter

diameter : 33mm

|

kr31,823.45

|

|

| |

length : 1 Meter

diameter : 33mm

|

kr40,410.75

|

|

| |

kr6,434.63

|

|

|

| |

length : 0.2 Meter

diameter : 34mm

|

kr11,582.14

|

|

| |

length : 0.3 Meter

diameter : 34mm

|

kr15,442.94

|

|

| |

length : 0.4 Meter

diameter : 34mm

|

kr19,732.60

|

|

| |

length : 0.5 Meter

diameter : 34mm

|

kr23,593.40

|

|

| |

length : 0.75 Meter

diameter : 34mm

|

kr33,781.38

|

|

| |

length : 1 Meter

diameter : 34mm

|

kr42,896.87

|

|

| |

kr6,818.65

|

|

|

| |

length : 0.2 Meter

diameter : 35mm

|

kr12,273.40

|

|

| |

length : 0.3 Meter

diameter : 35mm

|

kr16,364.67

|

|

| |

length : 0.4 Meter

diameter : 35mm

|

kr20,910.30

|

|

| |

length : 0.5 Meter

diameter : 35mm

|

kr25,001.57

|

|

| |

length : 0.75 Meter

diameter : 35mm

|

kr35,797.73

|

|

| |

length : 1 Meter

diameter : 35mm

|

kr45,457.38

|

|

| |

kr7,213.88

|

|

|

| |

length : 0.2 Meter

diameter : 36mm

|

kr12,984.98

|

|

| |

length : 0.3 Meter

diameter : 36mm

|

kr17,313.17

|

|

| |

length : 0.4 Meter

diameter : 36mm

|

kr22,122.47

|

|

| |

length : 0.5 Meter

diameter : 36mm

|

kr26,450.66

|

|

| |

length : 0.75 Meter

diameter : 36mm

|

kr37,872.51

|

|

| |

length : 1 Meter

diameter : 36mm

|

kr48,092.15

|

|

| |

kr8,466.26

|

|

|

| |

length : 0.2 Meter

diameter : 39mm

|

kr15,239.09

|

|

| |

length : 0.3 Meter

diameter : 39mm

|

kr20,318.93

|

|

| |

length : 0.4 Meter

diameter : 39mm

|

kr25,963.10

|

|

| |

length : 0.5 Meter

diameter : 39mm

|

kr31,042.80

|

|

| |

length : 0.75 Meter

diameter : 39mm

|

kr44,447.52

|

|

| |

length : 1 Meter

diameter : 39mm

|

kr56,441.42

|

|

| |

kr8,905.90

|

|

|

| |

length : 0.2 Meter

diameter : 40mm

|

kr16,030.67

|

|

| |

length : 0.3 Meter

diameter : 40mm

|

kr21,374.18

|

|

| |

length : 0.4 Meter

diameter : 40mm

|

kr27,311.45

|

|

| |

length : 0.5 Meter

diameter : 40mm

|

kr32,655.24

|

|

| |

length : 0.75 Meter

diameter : 40mm

|

kr46,756.27

|

|

| |

length : 1 Meter

diameter : 40mm

|

kr59,372.93

|

|

| |

kr9,818.80

|

|

|

| |

length : 0.2 Meter

diameter : 42mm

|

kr17,673.93

|

|

| |

length : 0.3 Meter

diameter : 42mm

|

kr23,565.10

|

|

| |

length : 0.4 Meter

diameter : 42mm

|

kr30,110.97

|

|

| |

length : 0.5 Meter

diameter : 42mm

|

kr36,002.28

|

|

| |

length : 0.75 Meter

diameter : 42mm

|

kr51,548.76

|

|

| |

length : 1 Meter

diameter : 42mm

|

kr65,458.70

|

|

| |

kr10,776.27

|

|

|

| |

length : 0.2 Meter

diameter : 44mm

|

kr19,397.19

|

|

| |

length : 0.3 Meter

diameter : 44mm

|

kr25,862.93

|

|

| |

length : 0.4 Meter

diameter : 44mm

|

kr33,046.96

|

|

| |

length : 0.5 Meter

diameter : 44mm

|

kr39,512.69

|

|

| |

length : 0.75 Meter

diameter : 44mm

|

kr56,575.08

|

|

| |

length : 1 Meter

diameter : 44mm

|

kr71,841.21

|

|