Inconel X-750 rod 2.4669 low-friction ams 5698 99, uns N07750, astm B 637 (length : 0.1 Meter, diameter : 39mm)

- Do you need a different steel quality or dimension? Please write to us. Our sales team makes an offer from stock program or delivery program :)

- Areas of application: components for gas turbines; combustion chamber of rocket engines; highly heat-resistant springs, screws and fasteners (up to 650 °C)

- Didn't find the sizes you wanted? Just contact us! We are happy to help you with your request

Length tolerance: +/-2mm

If you require a different grade of steel or specific dimensions, please contact us. Our sales team will be happy to provide a quote from our stock or delivery program.

- Production time: 2-3 business days.

- Preparation for shipment: 2-3 business days.

- Delivery time: Dependent on parcel service. Please refer to our FAQ for details.

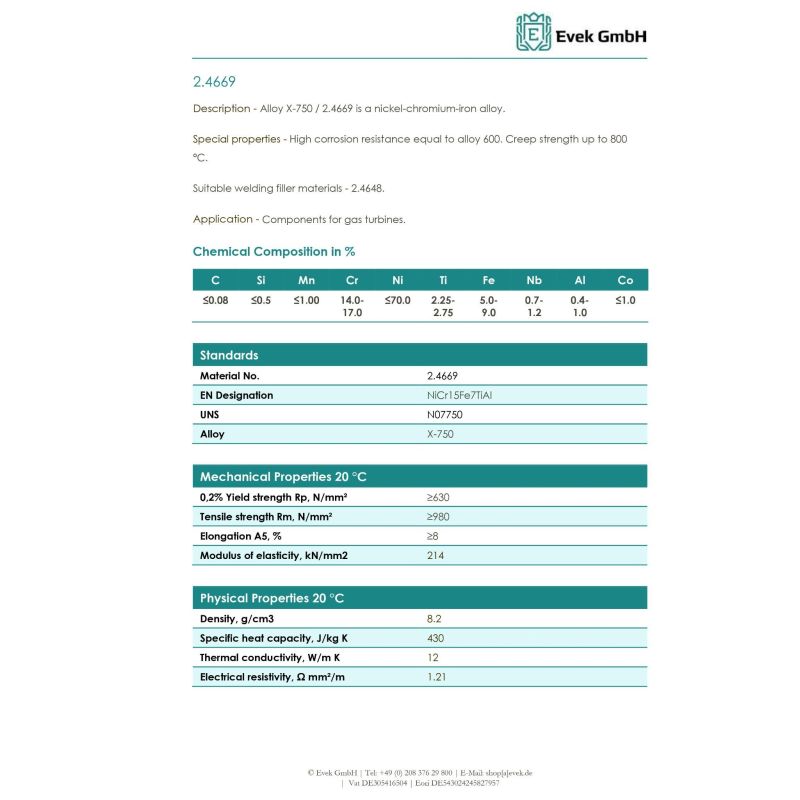

2.4669 is a hardenable nickel-chromium-iron alloy, with approximately 70% nickel and 15% chromium. It also contains about 7% iron, 2.5% titanium, and a combined 4% aluminium, niobium, cobalt, and manganese. Known as Alloy X-750, it offers excellent resistance to corrosion and oxidation, along with high strength at temperatures up to 700°C.

Evek GmbH is your trusted supplier for 2.4669. Purchase high-quality nickel alloys from us at competitive prices.

Alloy X-750 is commonly used for gas turbine components, and also finds applications in:

- Rocket engine combustion chambers

- Heat-resistant springs, screws, and fasteners (up to 650°C)

Main features of 2.4669 include:

- Excellent resistance to corrosion and oxidation

- High creep and heat resistance

- Very good relaxation resistance

Order Alloy X-750 and other nickel alloys easily in the Evek GmbH Online Shop at attractive prices.

- Type

- Round bar

- material

- Nickel alloy

- Alloy

- X-750

- density

- 8.28 g/cm³

- Thermal conductivity

- 12 W/(m-K)

- Electrical resistance

- 1.21 Ω mm²/m

-

-

| | Combination name | Price | |

| |

kr2,039.46

|

|

|

| |

length : 0.2 Meter

diameter : 24mm

|

kr3,671.10

|

|

| |

length : 0.3 Meter

diameter : 24mm

|

kr4,894.74

|

|

| |

length : 0.4 Meter

diameter : 24mm

|

kr6,254.38

|

|

| |

length : 0.5 Meter

diameter : 24mm

|

kr7,478.11

|

|

| |

length : 0.75 Meter

diameter : 24mm

|

kr10,707.25

|

|

| |

length : 1 Meter

diameter : 24mm

|

kr13,596.49

|

|

| |

kr2,581.23

|

|

|

| |

length : 0.2 Meter

diameter : 27mm

|

kr4,646.27

|

|

| |

length : 0.3 Meter

diameter : 27mm

|

kr6,194.93

|

|

| |

length : 0.4 Meter

diameter : 27mm

|

kr7,915.69

|

|

| |

length : 0.5 Meter

diameter : 27mm

|

kr9,464.45

|

|

| |

length : 0.75 Meter

diameter : 27mm

|

kr13,551.39

|

|

| |

length : 1 Meter

diameter : 27mm

|

kr17,208.14

|

|

| |

kr2,876.04

|

|

|

| |

length : 0.2 Meter

diameter : 28.5mm

|

kr5,176.81

|

|

| |

length : 0.3 Meter

diameter : 28.5mm

|

kr6,902.38

|

|

| |

length : 0.4 Meter

diameter : 28.5mm

|

kr8,819.66

|

|

| |

length : 0.5 Meter

diameter : 28.5mm

|

kr10,545.23

|

|

| |

length : 0.75 Meter

diameter : 28.5mm

|

kr15,098.90

|

|

| |

length : 1 Meter

diameter : 28.5mm

|

kr19,173.27

|

|

| |

kr3,186.63

|

|

|

| |

length : 0.2 Meter

diameter : 30mm

|

kr5,736.05

|

|

| |

length : 0.3 Meter

diameter : 30mm

|

kr7,648.06

|

|

| |

length : 0.4 Meter

diameter : 30mm

|

kr9,772.54

|

|

| |

length : 0.5 Meter

diameter : 30mm

|

kr11,684.56

|

|

| |

length : 0.75 Meter

diameter : 30mm

|

kr16,730.18

|

|

| |

length : 1 Meter

diameter : 30mm

|

kr21,244.55

|

|

| |

kr3,855.94

|

|

|

| |

length : 0.2 Meter

diameter : 33mm

|

kr6,940.62

|

|

| |

length : 0.3 Meter

diameter : 33mm

|

kr9,254.12

|

|

| |

length : 0.4 Meter

diameter : 33mm

|

kr11,824.75

|

|

| |

length : 0.5 Meter

diameter : 33mm

|

kr14,138.26

|

|

| |

length : 0.75 Meter

diameter : 33mm

|

kr20,243.45

|

|

| |

length : 1 Meter

diameter : 33mm

|

kr25,705.98

|

|

| |

kr4,093.18

|

|

|

| |

length : 0.2 Meter

diameter : 34mm

|

kr7,367.60

|

|

| |

length : 0.3 Meter

diameter : 34mm

|

kr9,823.52

|

|

| |

length : 0.4 Meter

diameter : 34mm

|

kr12,552.25

|

|

| |

length : 0.5 Meter

diameter : 34mm

|

kr15,008.17

|

|

| |

length : 0.75 Meter

diameter : 34mm

|

kr21,488.92

|

|

| |

length : 1 Meter

diameter : 34mm

|

kr27,287.44

|

|

| |

kr4,337.46

|

|

|

| |

length : 0.2 Meter

diameter : 35mm

|

kr7,807.32

|

|

| |

length : 0.3 Meter

diameter : 35mm

|

kr10,409.85

|

|

| |

length : 0.4 Meter

diameter : 35mm

|

kr13,301.40

|

|

| |

length : 0.5 Meter

diameter : 35mm

|

kr15,903.93

|

|

| |

length : 0.75 Meter

diameter : 35mm

|

kr22,771.56

|

|

| |

length : 1 Meter

diameter : 35mm

|

kr28,916.23

|

|

| |

kr4,588.87

|

|

|

| |

length : 0.2 Meter

diameter : 36mm

|

kr8,259.97

|

|

| |

length : 0.3 Meter

diameter : 36mm

|

kr11,013.21

|

|

| |

length : 0.4 Meter

diameter : 36mm

|

kr14,072.49

|

|

| |

length : 0.5 Meter

diameter : 36mm

|

kr16,825.72

|

|

| |

length : 0.75 Meter

diameter : 36mm

|

kr24,091.36

|

|

| |

length : 1 Meter

diameter : 36mm

|

kr30,592.25

|

|

| |

kr5,385.53

|

|

|

| |

length : 0.2 Meter

diameter : 39mm

|

kr9,693.85

|

|

| |

length : 0.3 Meter

diameter : 39mm

|

kr12,925.22

|

|

| |

length : 0.4 Meter

diameter : 39mm

|

kr16,515.58

|

|

| |

length : 0.5 Meter

diameter : 39mm

|

kr19,746.86

|

|

| |

length : 0.75 Meter

diameter : 39mm

|

kr28,273.84

|

|

| |

length : 1 Meter

diameter : 39mm

|

kr35,903.37

|

|

| |

kr5,665.20

|

|

|

| |

length : 0.2 Meter

diameter : 40mm

|

kr10,197.39

|

|

| |

length : 0.3 Meter

diameter : 40mm

|

kr13,596.49

|

|

| |

length : 0.4 Meter

diameter : 40mm

|

kr17,373.28

|

|

| |

length : 0.5 Meter

diameter : 40mm

|

kr20,772.56

|

|

| |

length : 0.75 Meter

diameter : 40mm

|

kr29,742.48

|

|

| |

length : 1 Meter

diameter : 40mm

|

kr37,768.15

|

|

| |

kr6,245.91

|

|

|

| |

length : 0.2 Meter

diameter : 42mm

|

kr11,242.69

|

|

| |

length : 0.3 Meter

diameter : 42mm

|

kr14,990.17

|

|

| |

length : 0.4 Meter

diameter : 42mm

|

kr19,154.11

|

|

| |

length : 0.5 Meter

diameter : 42mm

|

kr22,901.68

|

|

| |

length : 0.75 Meter

diameter : 42mm

|

kr32,791.06

|

|

| |

length : 1 Meter

diameter : 42mm

|

kr41,639.41

|

|

| |

kr6,854.97

|

|

|

| |

length : 0.2 Meter

diameter : 44mm

|

kr12,338.89

|

|

| |

length : 0.3 Meter

diameter : 44mm

|

kr16,451.85

|

|

| |

length : 0.4 Meter

diameter : 44mm

|

kr21,021.75

|

|

| |

length : 0.5 Meter

diameter : 44mm

|

kr25,134.71

|

|

| |

length : 0.75 Meter

diameter : 44mm

|

kr35,988.39

|

|

| |

length : 1 Meter

diameter : 44mm

|

kr45,699.44

|

|