Welding wire Hastelloy® C276 Nickel 2.4886 Ø 1.6-3.2mm TIG TIG welding rods Alloy

- Do you need a different steel quality or dimension? Please write to us. Our sales team makes an offer from stock program or delivery program :)

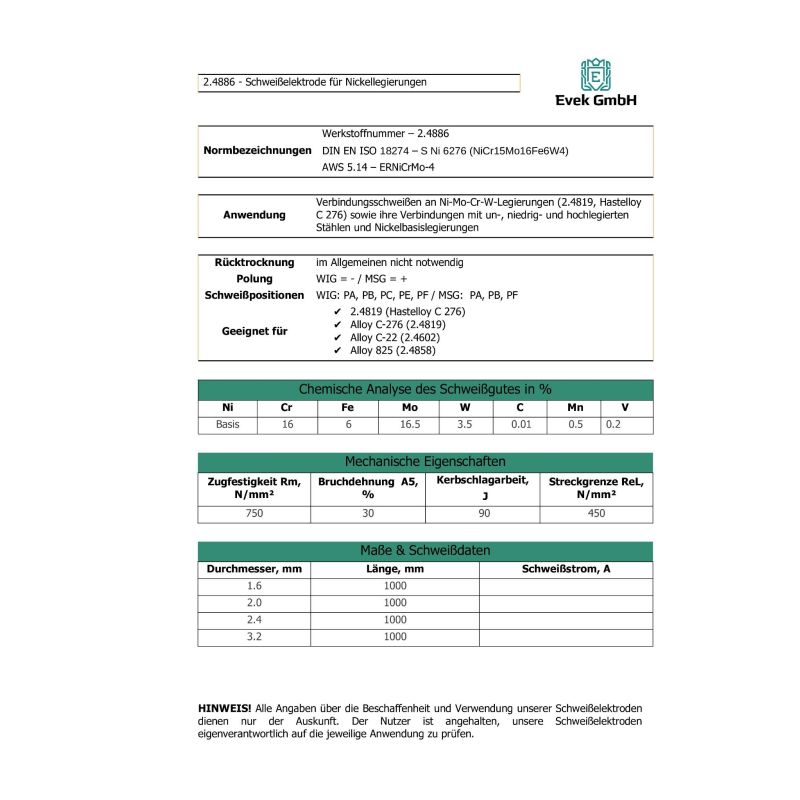

- Area of application: Joint welding of Ni-Mo-Cr-W alloys (2.4819, Hastelloy C 276) and their joints with non-, low- and high-alloy steels and nickel-based alloys;

- Wnr. 2.4886; DIN EN ISO 18274: S Ni 6276 (NiCr15Mo16Fe6W4); AWS A-5.14: ERNiCrMo-4

- Didn't find the sizes you wanted? Just contact us! We are happy to help you with your request.

Length tolerance +/-2mm

Do you need a different steel quality or dimensions? Please write to us. Our sales team makes an offer from stock program or delivery program :)

2.4886 is a nickel-molybdenum-chromium-tungsten alloy filler metal with an extremely low carbon content (0.01%). The 2.4886 filler metal has excellent corrosion resistance and provides excellent resistance to sulphurous acids in media containing chloride. No pre-heating or post-heating is required. The weld metal is widely used in the chemical industry and environmental technology.

You can find the 2.4886 welding wire in the Evek GmbH online shop. Other welding consumables are also available at good prices.

The 2.4886 filler metal is suitable for joint welding on Ni-Mo-Cr-W alloys (2.4819, Hastelloy C 276) and their connections with un-, low- and high-alloy steels and nickel-based alloys. Important base materials:

- 2.4819 (Hastelloy C 276)

- Alloy C-276 (2.4819)

- Alloy C-22 (2.4602)

- Alloy 825 (2.4858)

The 2.4886 welding wire has the following features:

- excellent corrosion resistance;

- extremely low carbon;

- excellent resistance to sulphurous acids in media containing chloride;

- for use in the chemical industry and environmental technology.

Buy 2.4886 welding filler from Evek GmbH, the competent supplier of high-quality semi-finished metal products. We ship worldwide.

- Type

- Welding electrodes

- material

- Nickel alloy

- Alloy

- C-276

- tensile strenght

- 750 N/mm²

- Stretch limit

- 450 N/mm²

- Elongation at break

- 30%