Nicrofer® S 7020 2.4806 alloy 82 Welding wire 0.8-1.6mm N06082 Nickel alloy Inconel® 82 (size : 0.8mm, Weight : 10 000 gr (10kg))

- Do you need a different steel quality or dimensions? Please contact us. Our sales team will make you an offer from our stock program or delivery program :)

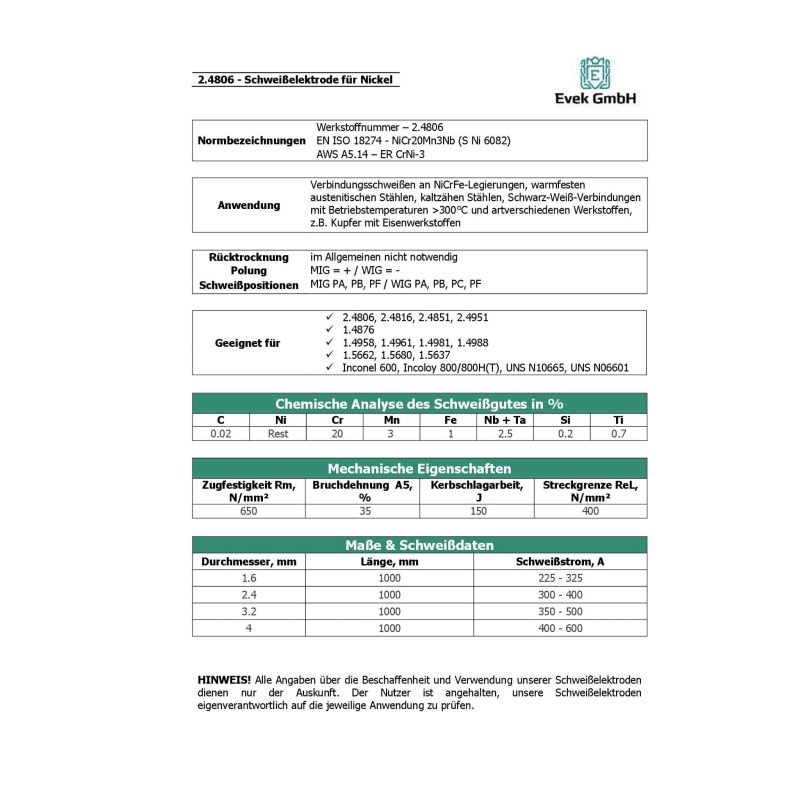

- Application: Joint welding on NiCrFe alloys, heat-resistant austenitic steels, cold-tough steels, black-white joints with operating temperatures >300°C and different types of materials, e.g. copper with ferrous materials;

- Wnr. 2.4806; EN ISO 18274: NiCr20Mn3Nb (S Ni 6082); AWS A5.14: ER CrNi-3

- Didn't find the sizes you were looking for? Just get in touch with us! We will be happy to help you with your request.

Customer ratings and reviews

Please note: The wire is usually delivered on a spool, but in some cases, it may be shipped as a coil without a spool. If you specifically require a spool, please check with us before placing your order.

Looking for a different steel grade or size? Contact our sales team for a customized offer from our extensive stock or delivery program.

2.4806 is a nickel-chromium-iron alloy welding wire with enhanced niobium (2.5%) and manganese (3%) content. This filler metal is especially well-suited for welding mixed joints between ferritic carbon-manganese and austenitic chromium-nickel steels. It offers excellent resistance to stress corrosion cracking and intergranular corrosion, maintains good toughness even at temperatures as low as -196°C, and is suitable for use at operating temperatures up to +900°C.

You can purchase high-quality 2.4806 welding wire from Evek GmbH Online Shop. Our team is available to provide advice and answer any questions you may have.

The 2.4806 welding wire is ideal for joining NiCrFe alloys, heat-resistant austenitic steels, cold-tough steels, and for black-white joints operating above 300°C, as well as for connecting different materials such as copper to ferrous metals. Common compatible base materials include:

- 2.4806, 2.4816, 2.4851, 2.4951

- 1.4876

- 1.4958, 1.4961, 1.4981, 1.4988

- 1.5662, 1.5680, 1.5637

- Inconel 600, Incoloy 800/800H(T), UNS N10665, UNS N06601

Key features of the 2.4806 welding wire:

- Suitable for dissimilar joints between ferritic carbon-manganese and austenitic chromium-nickel steels

- Maintains good toughness down to -196°C

- Withstands operating temperatures up to +900°C

Evek GmbH is your trusted supplier of 2.4806 welding consumables, offering high-quality products at competitive prices.

- Type

- Welding rod

- material

- Nickel alloy

- Material number

- 2.4806

- tensile strenght

- 650 N/mm²

- Stretch limit

- 400 N/mm²

- Elongation at break

- 35%

You might also like

Reviews

By

97helifan97

9.

on

(Nicrofer® S 7020 2.4806 alloy 82 Welding wire 0.8-1.6mm N06082 Nickel alloy Inconel® 82) :

(5/5)

By

stoiberman

S.

on

(Nicrofer® S 7020 2.4806 alloy 82 Welding wire 0.8-1.6mm N06082 Nickel alloy Inconel® 82) :

(5/5)

very fast shipping, everything...

very fast shipping, everything is fine, gladly again!

Report abuse

By

kostik975

K.

on

(Nicrofer® S 7020 2.4806 alloy 82 Welding wire 0.8-1.6mm N06082 Nickel alloy Inconel® 82) :

(5/5)

Good goods, delivered quickly,...

Good goods, delivered quickly, many thanks, gladly again

Report abuse