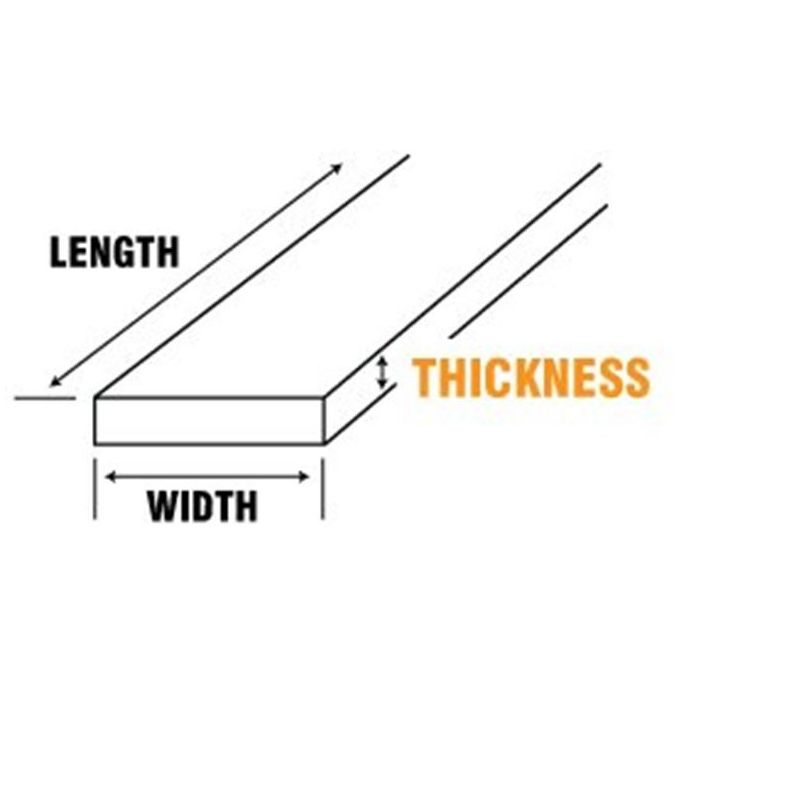

Haynes 25 Alloy L605(HS 25) Sheet 0.1-38.1mm 2.4964 Plate R30605 Cut to size 100-1000mm

- Applications: Aerospace industry; commercial gas turbine engines; combustion chambers and afterburners; high temperature ball bearings and bearing rings.

- Properties: good ductility; excellent high temperature resistance; good resistance to oxidizing environments; good weldability.

- Do you need other steel grades or dimensions? Please contact us. Our sales team will make an offer from stock or delivery program :)

- Did you not find the desired sizes? Just contact us! We will be happy to help you with your request

Length tolerance +/-2mm

Do you need a different steel quality or dimension? Please contact us. Our sales team will make you an offer from our stock program or delivery program :)

The tolerance for the width and length of a sheet metal blank is +/-2mm Important: Sheet metal blanks are not suitable for decorative or visible areas. Scratches are not excluded. Surface pure industrial quality. Cut with guillotine shears. Not all sheets in protective film. Please enquire separately if surface quality is relevant for you - we will try to find a solution for you.

- Production time - 5-7 weeks.

- Shipping preparation - 2-3 working days.

- Delivery time - depending on the parcel service. Please look at the faq.

HAYNES® 25 (UNS R30605) is a cobalt-nickel-chromium-tungsten alloy that combines excellent high temperature resistance with good resistance to oxidizing environments up to 980°C with prolonged exposure and excellent resistance to sulfidation. It can be produced and formed using conventional processes and has already been used for castings. Another attractive feature is its excellent resistance to metal wear.

The Haynes 25® alloy is the strongest of all workable cobalt alloys. It has excellent temperature and oxidation resistance up to 2000 °F. However, Haynes 25™ cobalt alloy is hot workable between 1900 °F and 2300 °F. In addition, alloy L605 is more suitable for bending, pressing and drawing operations than for cold forming.

Evek GmbH Online Shop offers the material 2.4964 and international delivery. As a reliable supplier for various materials, we ship safely and easily.

The HAYNES® 25 alloy is easy to form and weld. It can be forged or otherwise hot worked, provided it is held at 1205°C for long enough to bring the entire workpiece up to temperature. The alloy has good ductility and can therefore also be cold formed.

HAYNES® 25 is characterized by

- good ductility;

- excellent resistance to high temperatures;

- good resistance to oxidizing environments;

- good weldability.

Areas of application for HAYNES® 25 are:

- Aerospace industry;

- commercial gas turbine engines;

- Combustion chambers and afterburners;

- High temperature ball bearings and bearing rings.

If you want to buy the material 2.4964, you have come to the right place. Evek GmbH has a good price for various materials and will make a good offer on request if you have not found the product you are looking for.

- Type

- sheet

- material

- Nickel alloy

- Material number

- 2.4964