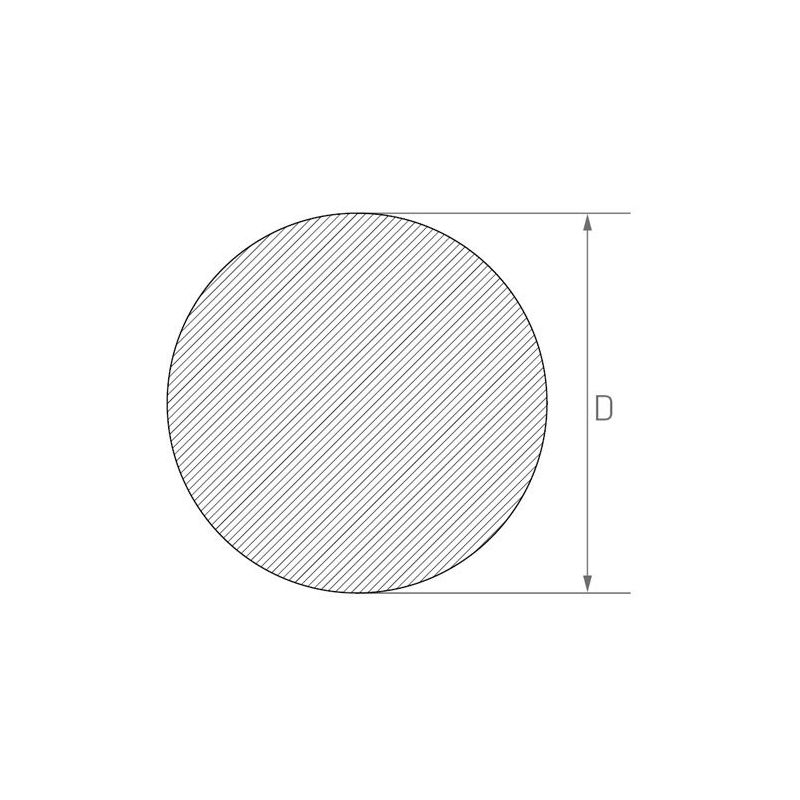

incoloy® 800 Alloy rod 10-160mm 1.4876 Round rod N08800 (length : 1 Meter x 10 st/pc, diameter : 10mm)

- Are you looking for material 1.4876 at a good price? You've come to the right place. We are happy to support you with help and advice and, as a reliable supplier, we deliver quickly and easily.

- Do you need a different steel grade or dimension? Please write to us. Our sales team will make you an offer from our stock program or delivery program :)

- Fields of application: Furnace construction (furnace muffles); heat treatment plants (burner components, parts); hydrogen production (parts); power plant construction (parts); environmental protection plants; quenching systems;

- Didn't find the sizes you were looking for? Simply contact us! We will be happy to help you with your request

Length tolerance: +/-2mm.

Production time is estimated at 5-7 weeks, with preparation for shipment taking an additional 2-3 business days. Delivery times depend on the chosen parcel service; please refer to our FAQ for more information.

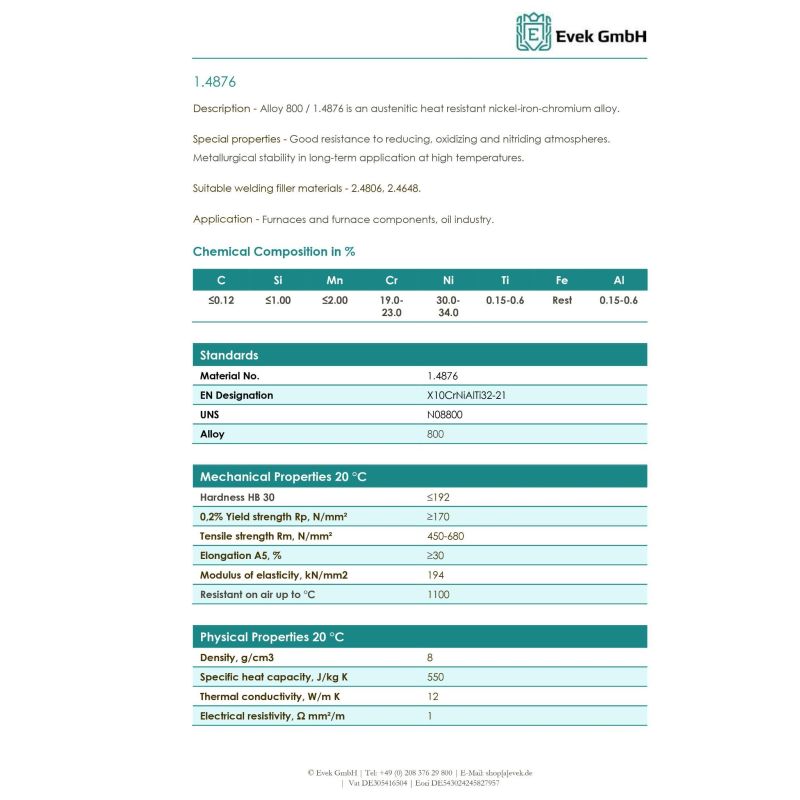

Material 1.4876 is an austenitic, heat-resistant nickel-iron-chromium alloy with low levels of manganese, silicon, aluminum, and titanium. It offers excellent resistance in oxidizing, reducing, and nitriding environments, and in certain temperature ranges, it is also resistant to sulphurous atmospheres. The alloy remains stable during prolonged use at elevated temperatures. In addition to its outstanding heat resistance, Incoloy 800 demonstrates high corrosion resistance. It effectively resists oxidation and carburization up to about 1000°C. The alloy is easy to work with, has good mechanical properties, and can be welded using all standard welding methods.

Purchase 1.4876 from Evek GmbH to benefit from high product quality. Our online shop is available 24/7. For further information about nickel alloys, please contact us directly.

Incoloy 800 is widely used across various industries. Typical applications include furnace construction (such as furnace muffles), components for heat treatment equipment (like burner parts), power plant construction, and hydrogen production.

Key properties of 1.4876 include:

- Excellent resistance in oxidizing, reducing, and nitriding media

- Resistant to sulphurous environments within certain temperature ranges

- Stable performance at high temperatures over the long term

- Superior heat resistance

- High corrosion resistance

- Oxidation and carburization resistance up to around 1000°C

- Good workability and mechanical strength

- Suitable for all common welding processes

Common uses for Incoloy 800 include:

- Furnace construction (furnace muffles)

- Heat treatment equipment (burner components, parts)

- Hydrogen production (components)

- Power plant construction

- Environmental protection systems

- Quenching systems

Looking for 1.4876 at a competitive price? You’re in the right place. We offer reliable support and fast, hassle-free delivery as your trusted supplier.

- Type

- Round bar

- material

- Nickel alloy

- Alloy

- 800

- density

- 8.0 g/cm³

- Melting point

- 1350 °C

- Thermal conductivity

- 11.5 W/(m - K)

- Electrical resistance

- 1.01 Ω mm²/m

You might also like

(5/5) on 4 rating(s)

£26.97

(5/5) on 5 rating(s)

£2,473.40

(5/5) on 4 rating(s)

£2,094.70

(5/5) on 4 rating(s)

£2,253.20

(5/5) on 4 rating(s)

£1,597.40

(5/5) on 4 rating(s)

£1,778.20

(5/5) on 4 rating(s)

£0.90

(4,8/5) on 5 rating(s)

£0.70

(5/5) on 4 rating(s)

£0.70

-

-

Select

Price: low-to-high

Price: high-to-low

| | Combination name | Price | |

| |

£1,870.80

|

|

|

| |

£2,694.00

|

|

|

| |

£1,500.00

|

|

|

| |

£1,683.70

|

|

|

| |

£1,718.80

|

|

|

| |

length : 1 Meter

diameter : 35mm

|

£2,291.80

|

|

| |

£2,245.00

|

|

|

| |

length : 1 Meter

diameter : 40mm

|

£2,993.30

|

|

| |

£1,515.40

|

|

|

| |

length : 0.5 Meter

diameter : 45mm

|

£1,894.20

|

|

| |

length : 0.75 Meter

diameter : 45mm

|

£2,841.30

|

|

| |

£1,870.80

|

|

|

| |

length : 0.5 Meter

diameter : 50mm

|

£2,338.50

|

|

| |

£1,931.20

|

|

|

| |

length : 0.5 Meter

diameter : 50.8mm

|

£2,414.00

|

|

| |

£2,020.50

|

|

|

| |

length : 0.4 Meter

diameter : 60mm

|

£2,694.00

|

|

| |

£1,833.40

|

|

|

| |

length : 0.3 Meter

diameter : 70mm

|

£2,750.10

|

|

| |

£2,104.70

|

|

|

| |

length : 0.3 Meter

diameter : 75mm

|

£3,157.00

|

|

| |

£2,394.60

|

|

|

| |

£1,515.40

|

|

|

| |

length : 0.2 Meter

diameter : 90mm

|

£3,030.70

|

|

| |

£1,688.40

|

|

|

| |

£1,870.80

|

|

|

| |

£2,474.20

|

|

|

| |

£1,580.80

|

|

|

| |

length : 0.1 Meter

diameter : 130mm

|

£3,161.70

|

|

| |

£1,833.40

|

|

|

| |

£2,104.70

|

|

|

| |

£2,394.60

|

|