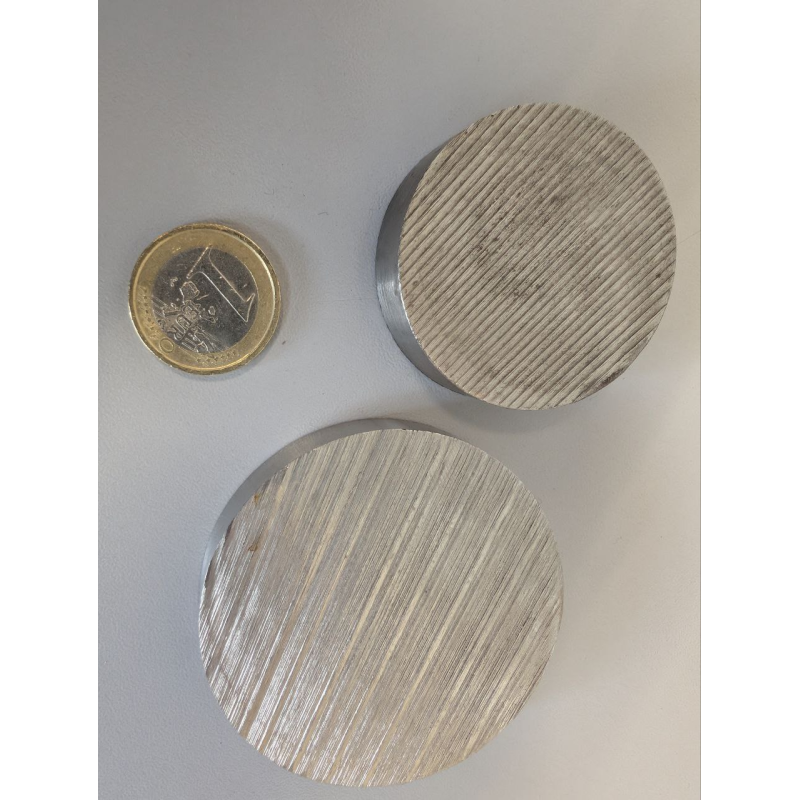

Stainless steel bar 25mm-50mm 1.4876 UNS N08800 Round bar profile Round steel

- Possible applications: Construction industry; apparatus engineering; automotive industry; chemical industry; petroleum industry; furnace construction; heating elements;

- Properties: good toughness; excellent oxidation and carbonization stability at high temperatures; high corrosion resistance; good creep resistance; metallurgical stability in long-term use; good heat resistance;

- Tolerance in cutting: +/-3mm.

- Didn't find the sizes you were looking for? Simply contact us! We will be happy to help you with your request.

Length tolerance +/-3mm

Do you need a different steel quality or dimension? Please contact us. Our sales team will make an offer from stock or delivery program :)

- Production time - 6-7 weeks.

- Preparation for shipment - 2-3 working days.

- Delivery time - depending on the parcel service. Please look at the faq.

Alloy 800 (UNS N08800) is nickel-iron-chromium alloys designed to resist oxidation and carburization at elevated temperatures. The 32% nickel content makes the alloys highly resistant to both chloride stress corrosion cracking and embrittlement due to sigma phase precipitation. The general corrosion resistance is excellent. In the solution-annealed condition, Alloy 800 has excellent creep and stress fracture properties.

The chromium and nickel contents of Alloy 800 are higher than those of the well-known stainless steel alloy Alloy 304. Under many service conditions, the performance of Alloy 800 and Alloy 304 is similar. For example, comparable behavior can be expected in most rural and industrial atmospheres and in chemical media such as nitric acid and organic acids. Neither Alloys 800, 800H and 800HT nor Alloy 304 are recommended for sulphuric acid applications except at lower concentrations and temperatures. Like austenitic stainless steels, alloys 800, 800H and 800HT are subject to sensitization (precipitation of chromium carbides at the grain boundaries) when heated for excessive periods in the 538-760 °C temperature range. The sensitized metal may be subject to intergranular attack by certain corrosive agents, including pickling acids or the boiling 65% nitric acid test.

The material 1.4876 is available in the Evek GmbH online store at a good price. Buy high-quality round bars with worldwide shipping.

Typical applications of 1.4876 round bar are:

- Construction industry;

- Apparatus engineering;

- automotive industry

- chemical industry;

- petroleum industry;

- furnace construction;

- heating elements;

The material 1.4876 is characterized by the following properties:

- good toughness

- excellent oxidation and carbonization stability at high temperatures;

- high corrosion resistance;

- good heat resistance;

- good creep resistance;

- metallurgical stability in long-term use;

Evek GmbH is your competent supplier for 1.4876. Procure steel materials of the highest quality.

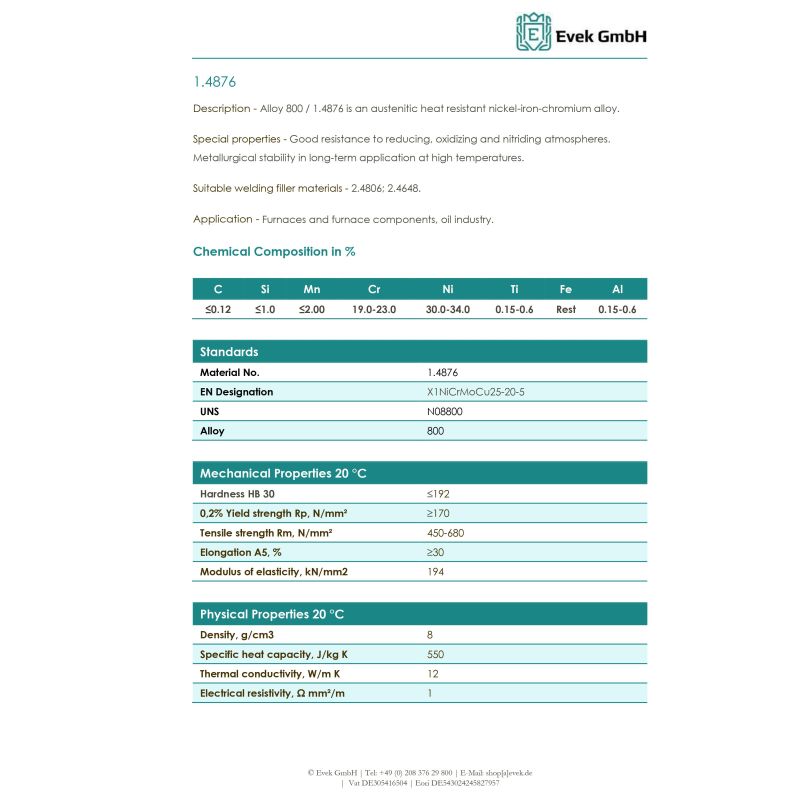

- material

- Stainless steel

- Material number

- 1.4876

- EN

- X10CrNiAlTi32-21

- US

- N08800

- Alloy

- 800

- density

- 8.0 g/cm³

- Thermal conductivity

- 12 W/(m-K)

- Electrical resistance

- 1 Ω mm²/m